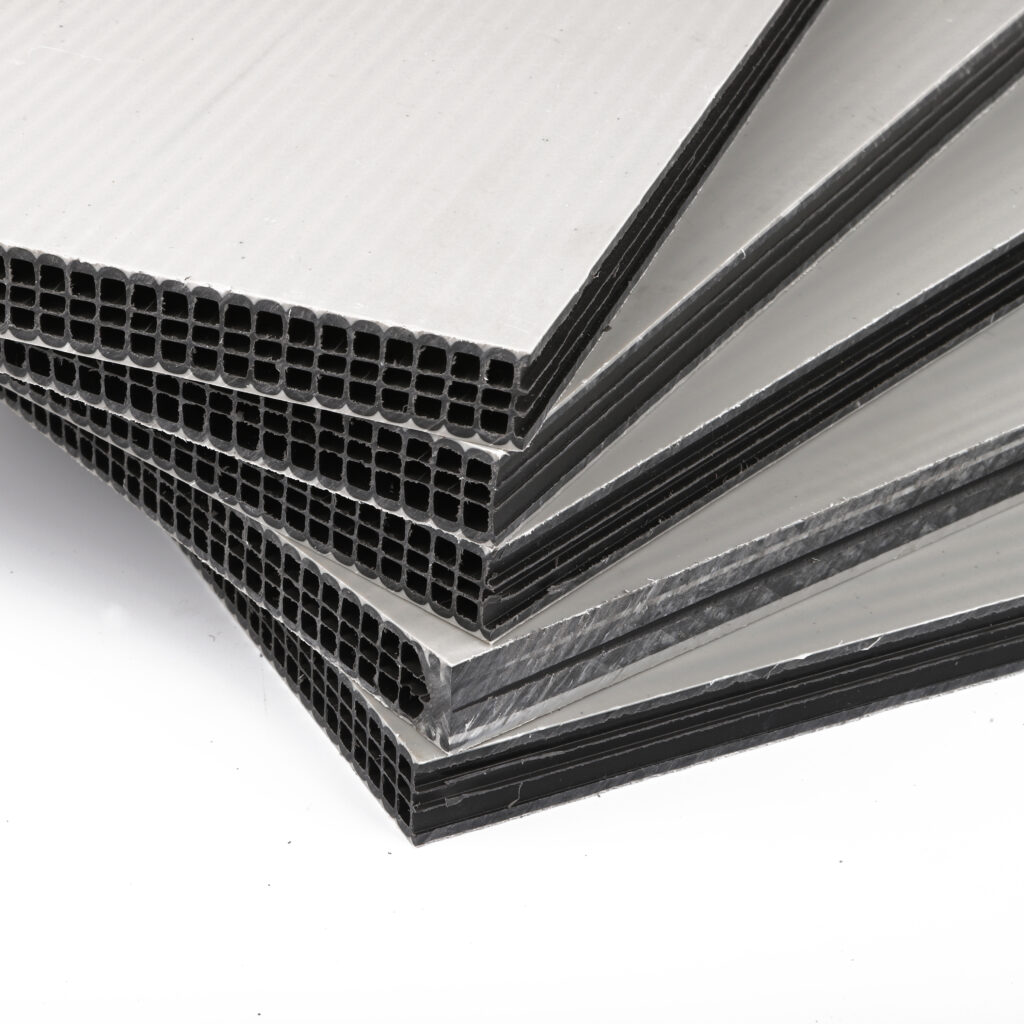

Co-extrusion PVC Board are using the co-extrusion process. It’s like a sandwich panel, it’s the same material for core and surfaces. The core is foam PVC and two sides skin are rigid PVC. That particular process makes the product unique performance. Provides a hard surface for both thin sheets and thick boards White co-extruded foam PVC sheets represent a reliable selection of plastic sheets for a variety of applications in the field of visual communication.

In structural applications such as substrate printing or used as creative, coloured or co-extruded robust sheets.

This sheet combines the extra-tough surface quality of solid PVC with the lightweight, easy-to-use characteristics of a foam PVC core.

It has an ultra-smooth surface that offers excellent ink-adhesion for digital and screen printing applications.

It’s easy to fabricate, can be cold-bent with a v-groove cut, and provides good mechanical strength and excellent chemical resistance.

Coloured co-extrusion PVC Foam Board is robust and hard-wearing. It is versatile and long-lasting, making it an economical choice for a range of indoor and outdoor projects.

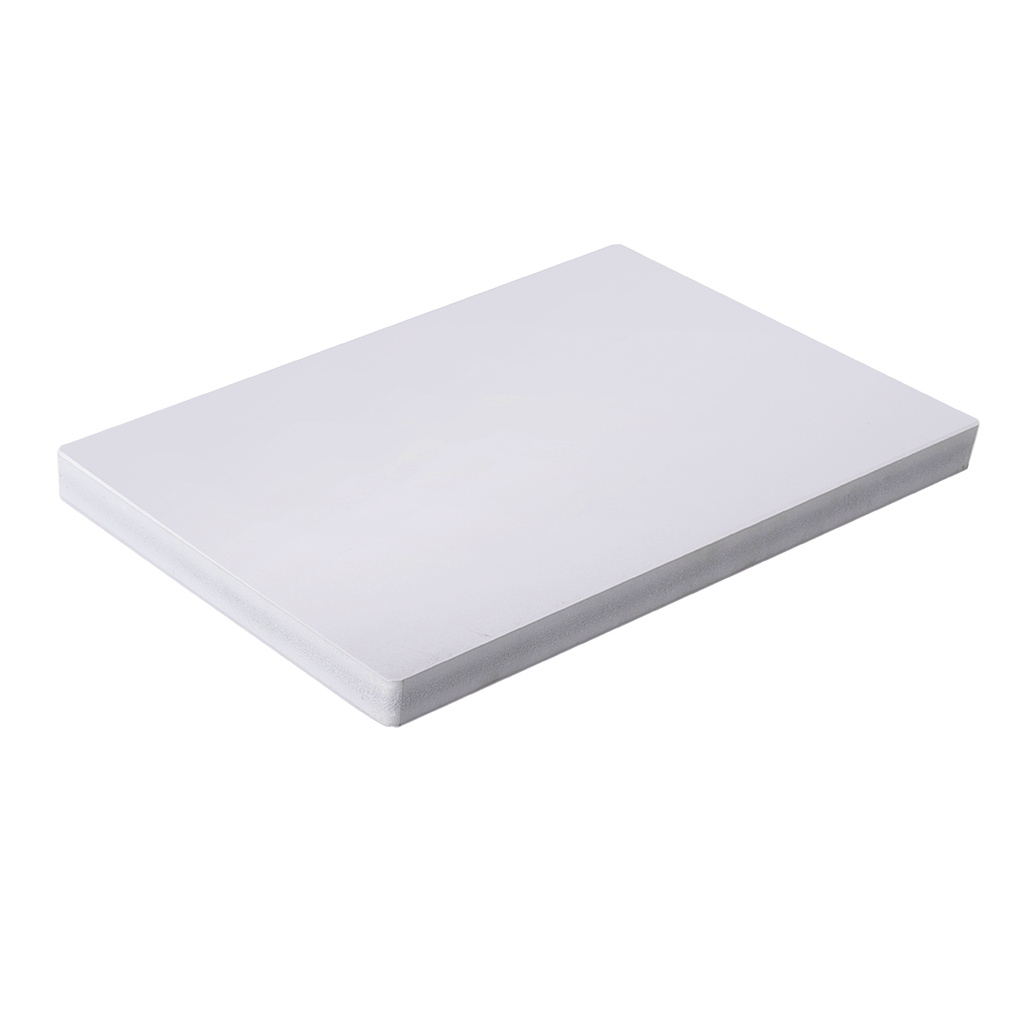

White co-extruded pvc foam board

White co-extruded pvc foam board is using the co-extrusion production process, which forms a sandwich board structure-the core is cellular pvc and both outer skin is rigid pvc. It is a lightweight, expanded rigid PVC foam board that is used for a variety of applications including signs and display, exhibit booths, photo mounting, interior design, thermoforming, prototypes, model making. Compared with PVC celuka foam board, PVC co-extruded foam has a smoother and shiny surface. Surface harness is much better than celuka, which will benefit from using in some applications, such as table top, interior decoration for boats, ships, vehicles, trains.

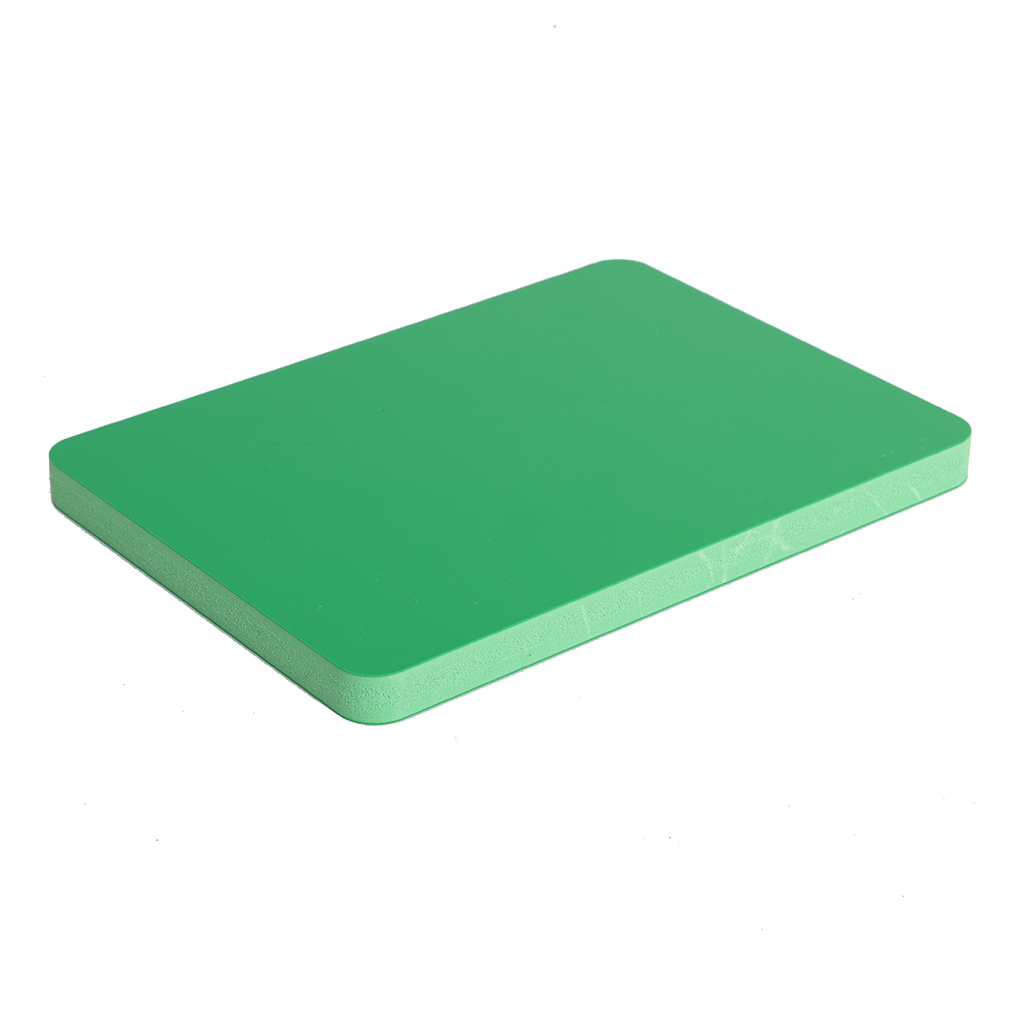

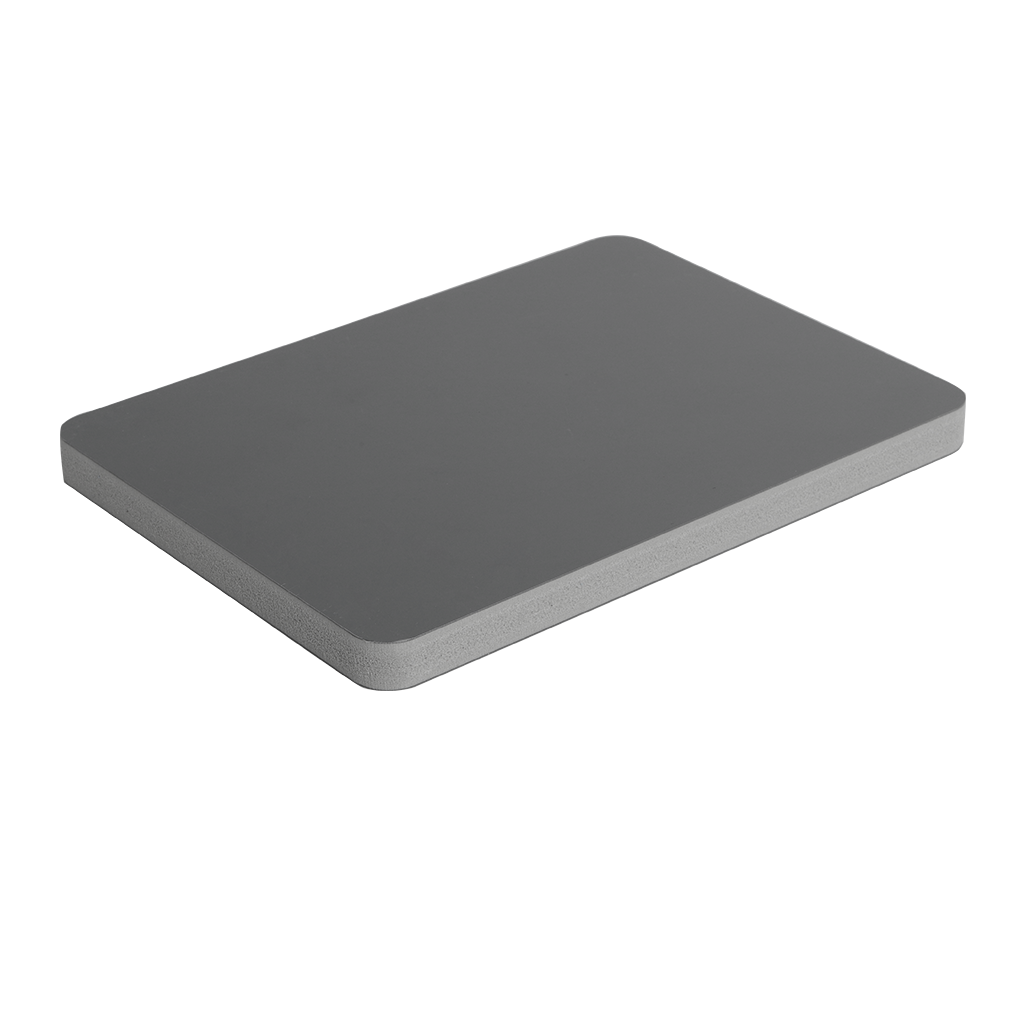

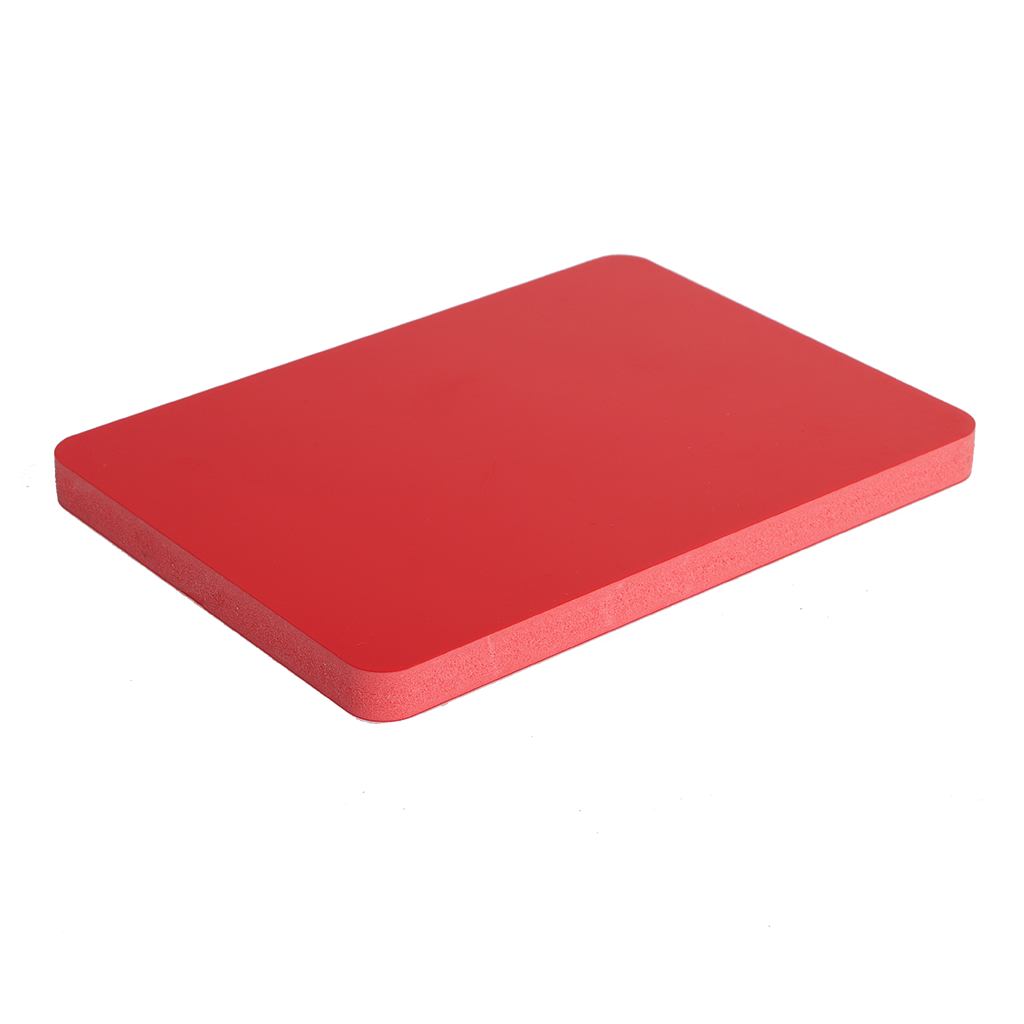

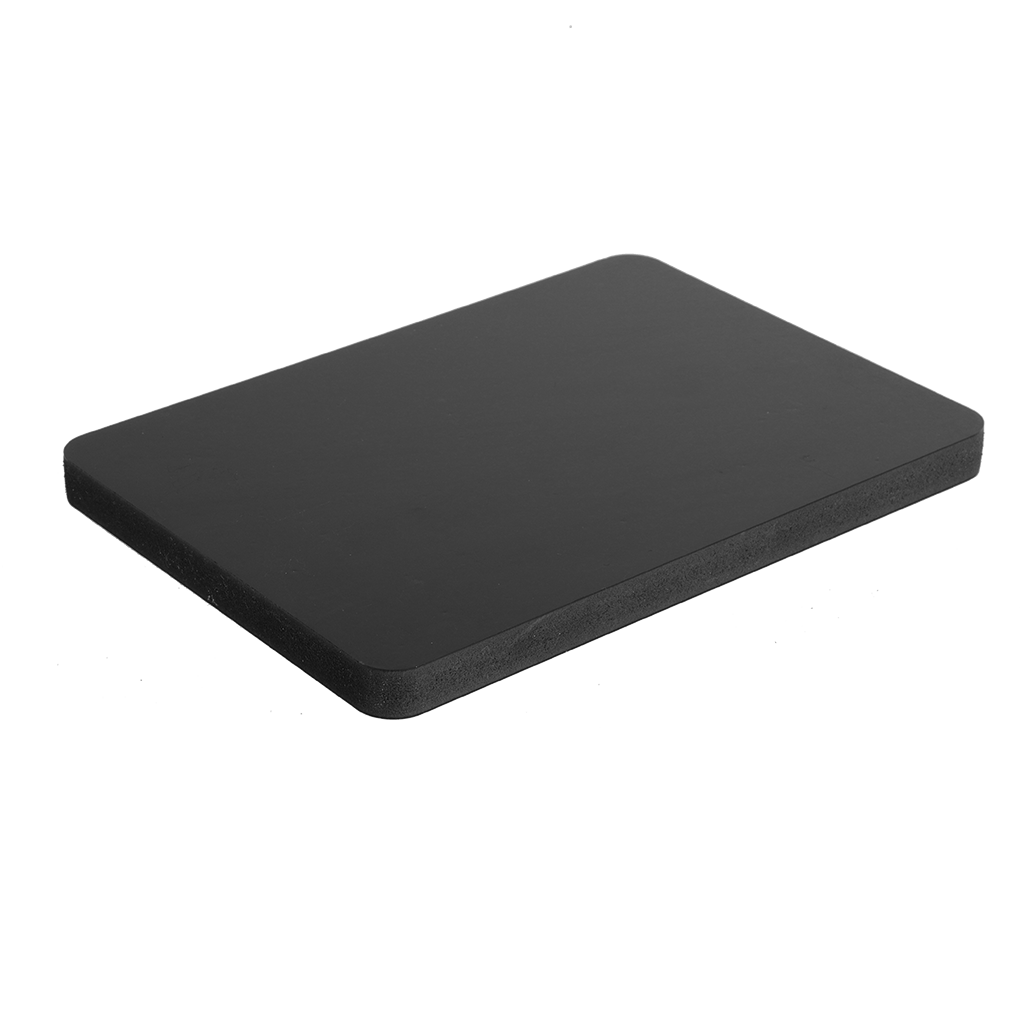

Colored PVC Co-extruded foam Board

PVC Co-extruded colored foam sheet is a kind of PVC Foam Board, which is manufactured by Co-extruded foaming machine. Its main ingredients include PVC resin and special additives like foaming agent, anti-aging agent, colorant. etc.

Our company mainly produces: red pvc board, blue pvc board, white pvc board, green pvc board, black pvc board and other color pvc boards and foam boards.

The sheet has a flat glossy surface and excellent face hardness. Because of its coating-free and water-proof character, it is widely applicable to indoor and outdoor decoration.

Coloured:

White

Blue

Yellow

Green

Grey

Red

Black

Processing options

PVC sheets are easy to process. We are happy to explain the various processing options for foamed and hard PVC.

Process foamed PVC (foam sheet)

Foamed PVC can be sawn, cut, drilled, painted and bent. The surface is flat and smooth and can be printed and inscribed very well.

Cutting

Drilling

Sawing

Sawing (jigsaw)

Sawing (circular saw)

Glueing

Bending (warm)

Painting

Nailing