Automotive, Marine & Transportation

Plastic Sheets: Revolutionizing Automotive, Marine, and Transportation Industries

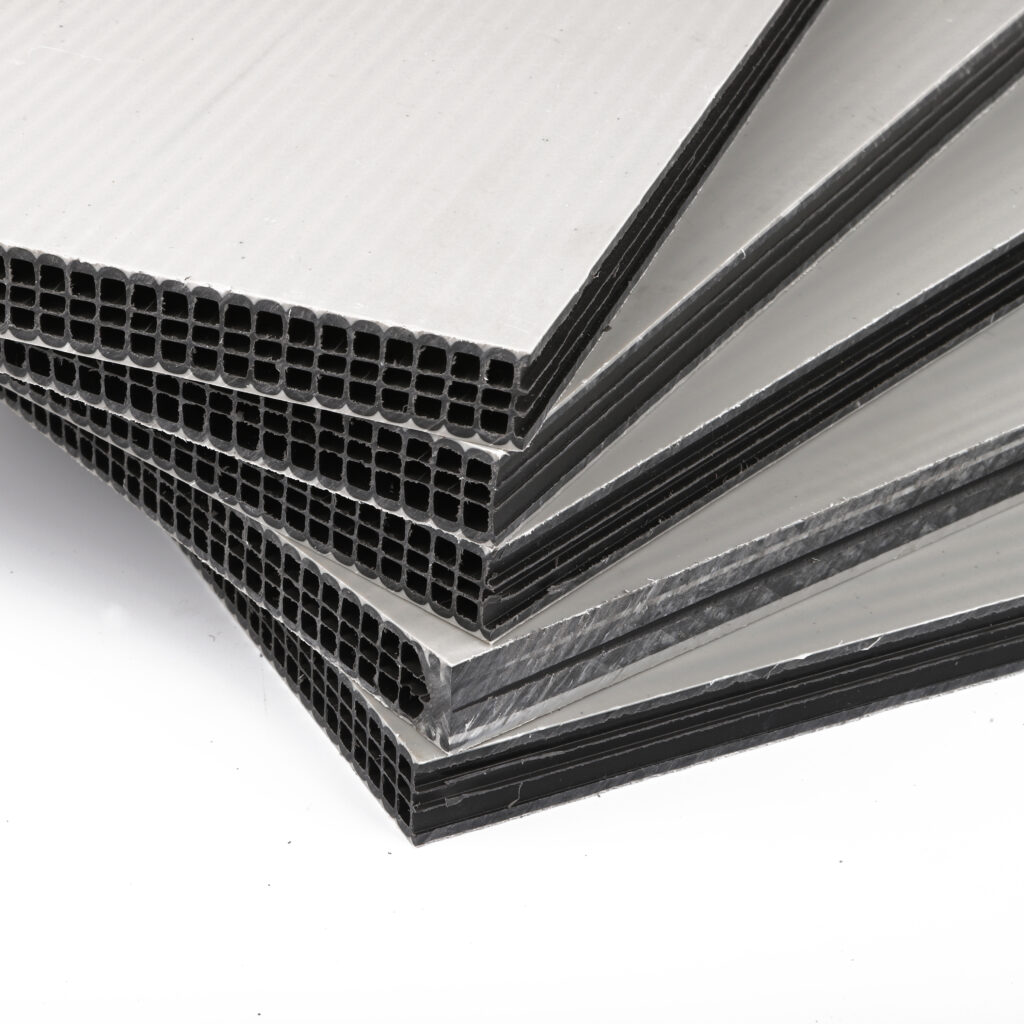

Plastic sheets have become an integral part of the automotive, marine, and transportation sectors due to their unique properties and wide-ranging applications. At Kingstar Building Material, we offer a diverse range of plastic sheets that are designed to meet the specific demands of these industries.

Applications in Automotive, Marine, and Transportation:

Automotive Industry: Bumpers and Body Parts: Plastic sheets like PP, ABS, and PC are used in the manufacturing of car bumpers and body components due to their high impact resistance and ability to retain shape under stress

Interior Components: Materials such as PVC and PUR are utilized for flexible foam seating, dashboards, and interior trim, offering comfort, durability, and design flexibility

Lightweighting: Polycarbonate sheets are recognized for their transparency and are used in manufacturing vehicle lighting systems, including headlights and taillights

Marine and Naval Applications:

Hull and Decking: High-strength plastic sheets are used in the construction of hulls and decking, providing lightweight and corrosion-resistant solutions for marine vessels

Equipment Housings: Plastic sheets offer protection against water and salt corrosion, making them ideal for housing marine electronics and mechanical equipment

Transportation Infrastructure:

Railway Components: Plastic sheets are used in the manufacturing of railway parts such as insulation boards, padding, and Baffle seat, contributing to the lightweight construction and durability of train components

Road Signage and Barriers: Plastic sheets are employed in the production of road signs, traffic barriers, and safety markers, offering long-lasting visibility and resistance to environmental wear

Technical and Design Considerations:

Material Selection: The choice of plastic sheet is crucial and depends on the specific requirements of each application, such as resistance to chemicals, weather, and mechanical stress

Sustainability and Lightweighting: Plastic sheets contribute to the sustainability and efficiency of vehicles by reducing weight and improving fuel economy, which in turn lowers emissions

Customizability: The ability to customize plastic sheets in terms of size, shape, and material allows for the creation of specialized parts that meet the unique demands of each industry segment.

Showing 1–9 of 10 results

-

Extrued Acrylic-Plastic Sheet

Read more -

PVC Laminated Foam Board-Plastic Sheet

Read more -

PVC Grey Free Foam Plastic Sheet – 2mm Thick

Read more -

White PVC Free Foam 8 mm Thick Plastic Sheet

Read more -

PVC White Free Foam Plastic Sheet – 7mm Thick

Read more -

PVC White Free Foam Plastic Sheet – 6mm Thick

Read more -

PVC White Free Foam Plastic Sheet – 5mm Thick

Read more -

PVC White Free Foam Plastic Sheet – 4mm Thick

Read more -

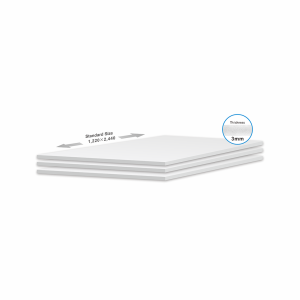

PVC White Free Foam Plastic Sheet – 3mm Thick

Read more