Electronics & Energy

Plastic Sheets: Driving Innovation in Electronics and Energy Industries

Plastic sheets are playing a crucial role in the electronics and energy sectors, offering innovative solutions for a range of applications. At Kingstar Building Material, we provide a variety of plastic sheets that are specifically tailored to meet the demanding requirements of these industries.

Applications in Electronics & Energy:

- Solar Energy Applications:

- Plastic sheets are revolutionizing solar panel manufacturing. Materials like Quentys Packaging film from Borouge offer excellent UV resistance and waterproof properties, contributing to the durability and longevity of solar panels without the need for chemical reactions during lamination .

- High-Density Polyethylene (HDPE) is used in floating photovoltaic (FPV) systems, providing food-grade materials that enhance durability and recyclability .

- Wind Energy Innovations:

- Advanced polymer materials are creating opportunities for the design of longer and lighter wind turbine blades, reducing static and dynamic loads and extending the lifespan of the blades. Polyurethane (PU) resins and coatings offer a cost-effective alternative to traditional glass fiber-reinforced epoxy resins, enhancing the mechanical properties of the blades .

- Hydrogen Energy and Electrical Networks:

- The development of hydrogen energy and water networks relies on reliable gas and water pipes. Plastic pipes, such as PE and HDPE, are more durable, chemical-resistant, and corrosion-resistant compared to metal or concrete, and they are lightweight and easy to install .

- Battery Technology:

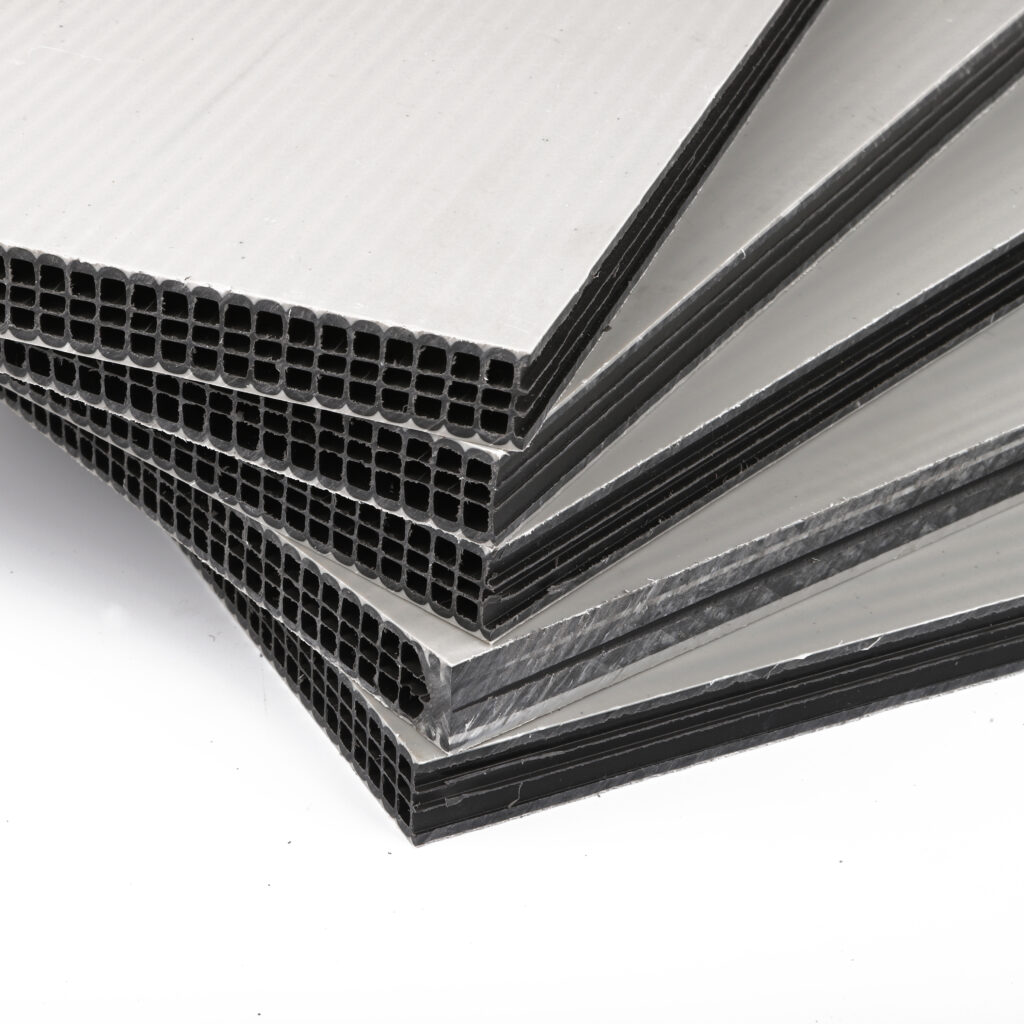

- For off-grid renewable energy, lithium-ion batteries are the primary energy storage devices. Traditional current collectors are made from aluminum and copper foils, but new “metal-polymer-metal” structured composite current collector films offer higher safety .

- Electronic and Communication Products:

- Engineering plastics like PC, POM, MPPO, and PBT are commonly used in the electronics industry for their superior mechanical, electrical, and thermal properties .

- High-performance engineering plastics like Ultem and Extem from GE are used in applications requiring high-temperature resistance and chemical corrosion resistance, such as in defense, oil and gas processing, aviation, automotive, electronics, and semiconductor wafer processing .

Technical and Design Considerations:

- Material Selection: The choice of plastic sheet is based on specific application requirements, such as resistance to chemicals, weather, and mechanical stress.

- Customization: Plastic sheets can be customized in terms of size, shape, color, and texture, allowing for the creation of unique components that meet the unique demands of the electronics and energy industries.

- Innovative Finishes: Plastic sheets offer a broad range of finishes, providing designers with the flexibility to achieve the desired aesthetic and functionality.