Fabrication

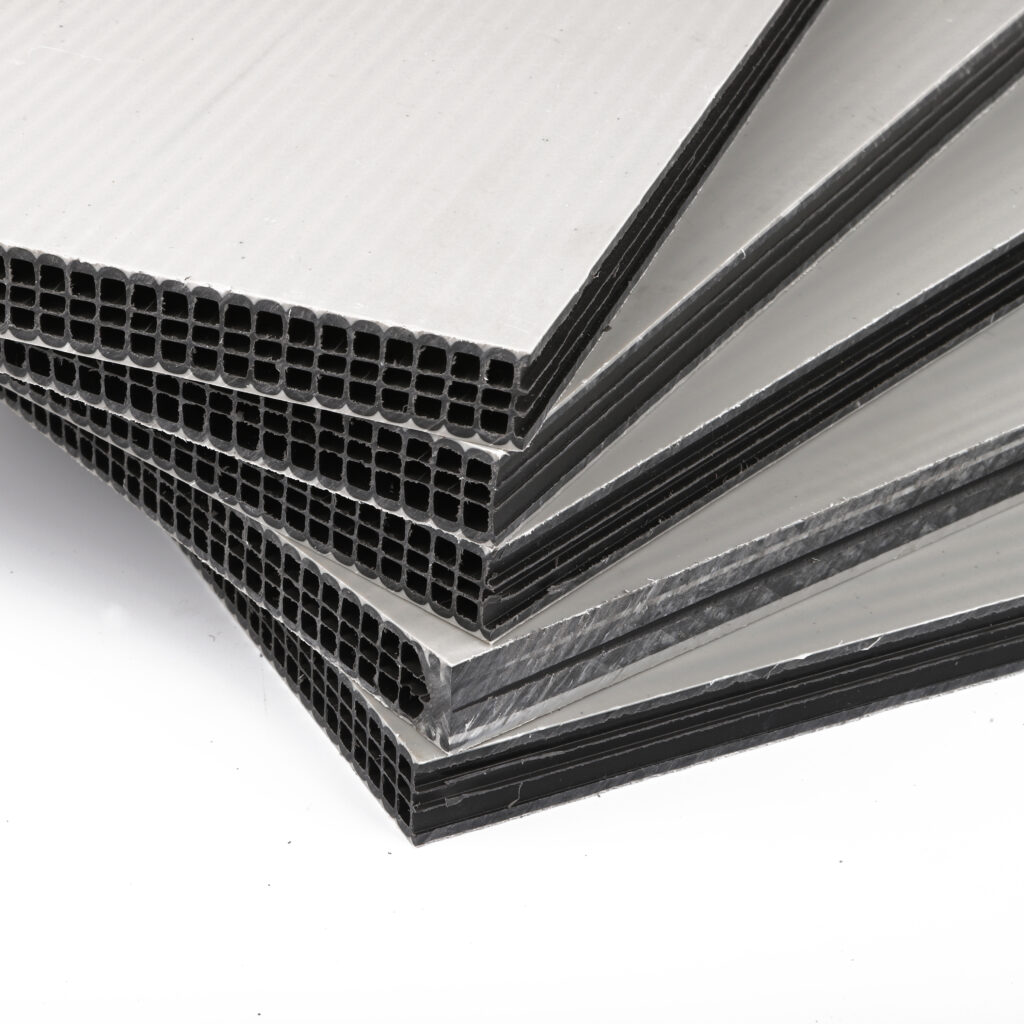

Acrylic, PE, and PVC Sheets: Versatile Materials for Fabrication

Acrylic, PE, and PVC sheets are widely used in the fabrication industry due to their unique properties and the ability to be shaped and formed into various products. These materials offer a range of solutions from simple to complex fabrication projects.

Applications of Acrylic Sheets in Fabrication:

Transparent Displays and Signage: Acrylic sheets are known for their high light transmittance and clarity, making them ideal for creating transparent displays and signage that require a polished, professional finish

Custom Parts and Components: Acrylic’s ability to be thermoformed or mechanically processed allows for the creation of custom parts and components with intricate details and designs

Applications of PE Sheets in Fabrication:

Chemical Processing Components: PE sheets, with their excellent chemical resistance, are used in the fabrication of components for chemical processing and storage tanks

Automotive and Industrial Applications: PE’s impact resistance and durability make it suitable for fabrication in the automotive industry for parts like bumpers and protective covers

Applications of PVC Sheets in Fabrication:

Construction and Building Materials: PVC sheets are used in the fabrication of construction materials such as wall cladding, ceiling panels, and door frames due to their moisture resistance and durability

Outdoor Furniture and Structures: PVC’s resistance to weathering makes it a popular choice for outdoor furniture and structures that require low maintenance and long-lasting performance

Fabrication Techniques and Considerations:

CNC Machining: All three materials can be precision-cut and shaped using CNC machining, which is ideal for creating complex geometrical features and tight tolerances

Thermoforming: Acrylic and PVC sheets are particularly well-suited for thermoforming, where heat is used to make the sheets pliable and form them into the desired shape

3D Printing: While not traditionally used for 3D printing, advancements in additive manufacturing have made it possible to 3D print with a variety of plastics, including acrylic and PVC, offering new opportunities for rapid prototyping and small-batch production