- Products

- Applications

- Resource Center

TECHNICAL GUIDES & DATA SHEETS

MATERIAL SELECTION TOOLS

- Contact Us

- About Us

KINGSTAR

Leverage the strength and reliability of PP Rigid Board for your next project. Contact Kingstar Building Material today to explore our range of PP Rigid Boards and discuss how they can meet your specific requirements.

Whatever your inquiry, at Kingstar we’re here to help.

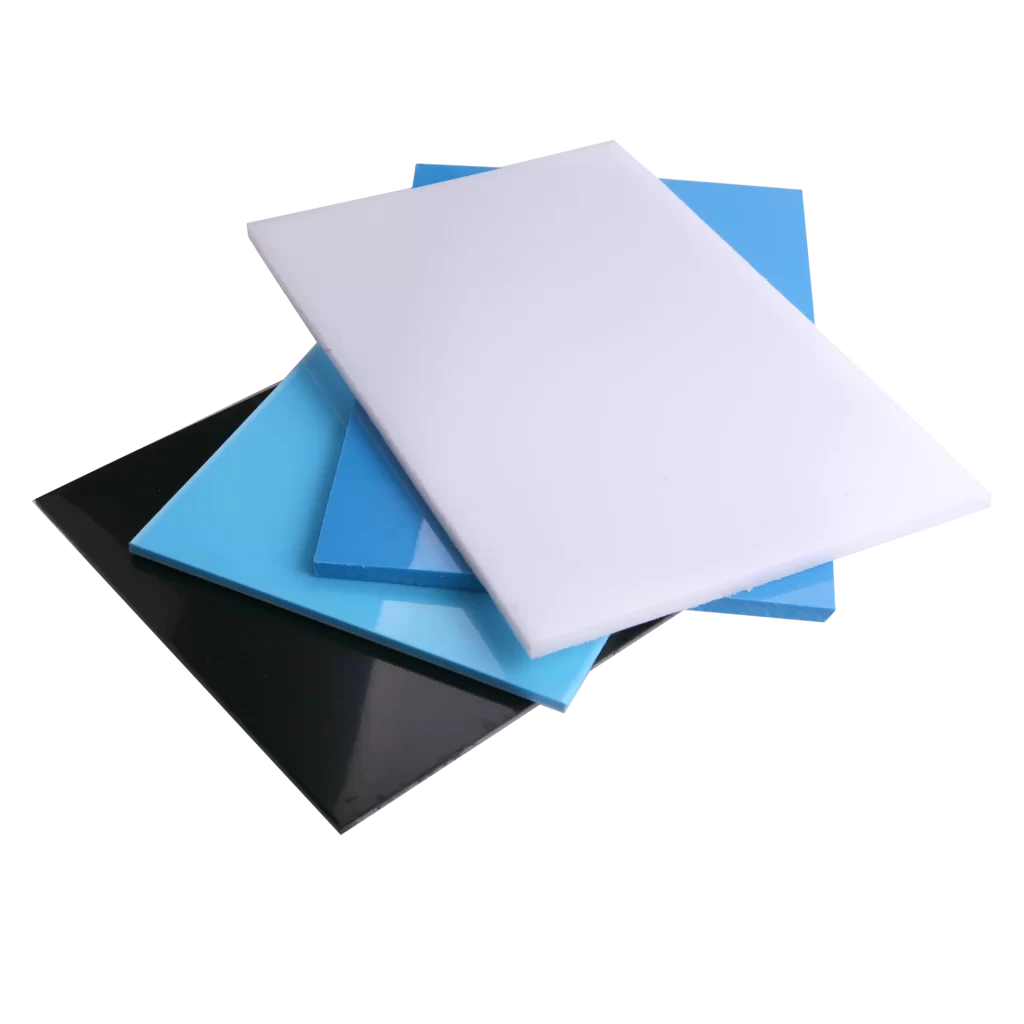

PP Rigid Board: Engineered Plastic Excellence for Diverse Applications

PP Rigid Board, also known as polypropylene (PP) board, is a semi-crystalline material known for its superior chemical resistance, Polypropylene sheets are highly durable and flexible materials that are widely known for their ability to resist impacts and corrosive chemicals. They are versatile plastic sheets that can be used in a variety of applications.

Polypropylene sheet is celebrated for its high resistance to chemicals in environments where it may come into contact with corrosive substances. In addition to its excellent chemical resistance, it is also resistant to fatigue and can be fabricated, machined and thermoformed.

Commonly utilised in engineering and manufacturing, polypropylene is a popular plastic choice due to its exceptional resistance to acids and other chemicals. In addition to being highly durable, it is also a cost-effective option. These sheets can withstand high levels of impact and have a low tendency to absorb water, making them suitable for a wide range of applications.

What are the advantages of Polypropylene?

Polypropylene is a versatile plastic that is often used in the manufacturing of products such as food containers, packaging materials, and building insulation. It is also commonly used to make bottles and other containers for liquids.

Some of the advantages of Polypropylene include its strong resistance to scratches, drips, and gas emissions. Additionally, it can be easily printed or coloured without suffering from distortion or fading. This makes it a good choice when you need high-quality labelling or graphics on your product. Furthermore, Polypropylene Sheet does not release compounds that may cause environmental damage.

What are the disadvantages of Polypropylene?

While Polypropylene Sheets offer numerous advantages, there are also a few potential drawbacks to consider. For example, they can be vulnerable to UV degradation, meaning that prolonged exposure to sunlight can cause them to become brittle and crack over time. Additionally, while they are resistant to many chemicals, they may not be suitable for use with certain types of solvents or other corrosive materials. Finally, while they are generally strong and impact-resistant, they may not be the best choice for applications where high-temperature resistance is required. It’s important to carefully consider the specific requirements of your project and the potential limitations of Polypropylene Sheets before making a decision about whether or not they are the right material for your needs.

Key Features:

Extremely high chemical resistance

High fatigue resistance

High impact resistance

Impermeable to water vapour

Low cost

Will withstand repeated steam cleaning

Suitable for hygienic situations

Its resistance to fatigue is thanks to the ‘inherent hinge property’, which means the material will withstand repeated flexing and movement. Polypropylene is an incredibly strong material, which is also impermeable to water vapour and will withstand repeated steam cleaning.

This makes it an excellent cost-effective choice for hygienic wall cladding in applications such as food preparation areas, hospitals, care homes and anywhere where an easy to maintain hygienic wall covering is needed.

Please Note: Polypropylene is an engineering/industrial grade material which may have imperfections in the surface – we therefore would not recommend this material is used for aesthetic purposes.

Key Features:

Applications:

Technical Specifications:

Let’s get this conversation started. Tell us a bit about yourself, and we’ll get in touch as soon as we can.

Your email address will only be used to respond to your inquiry. The information you submit will be governed by our Privacy Policy

Quote plastic, custom projects. Put us to work for you!

Fill out the form below, and we will be in touch shortly.