Sawing PVC: 3 ways to do it

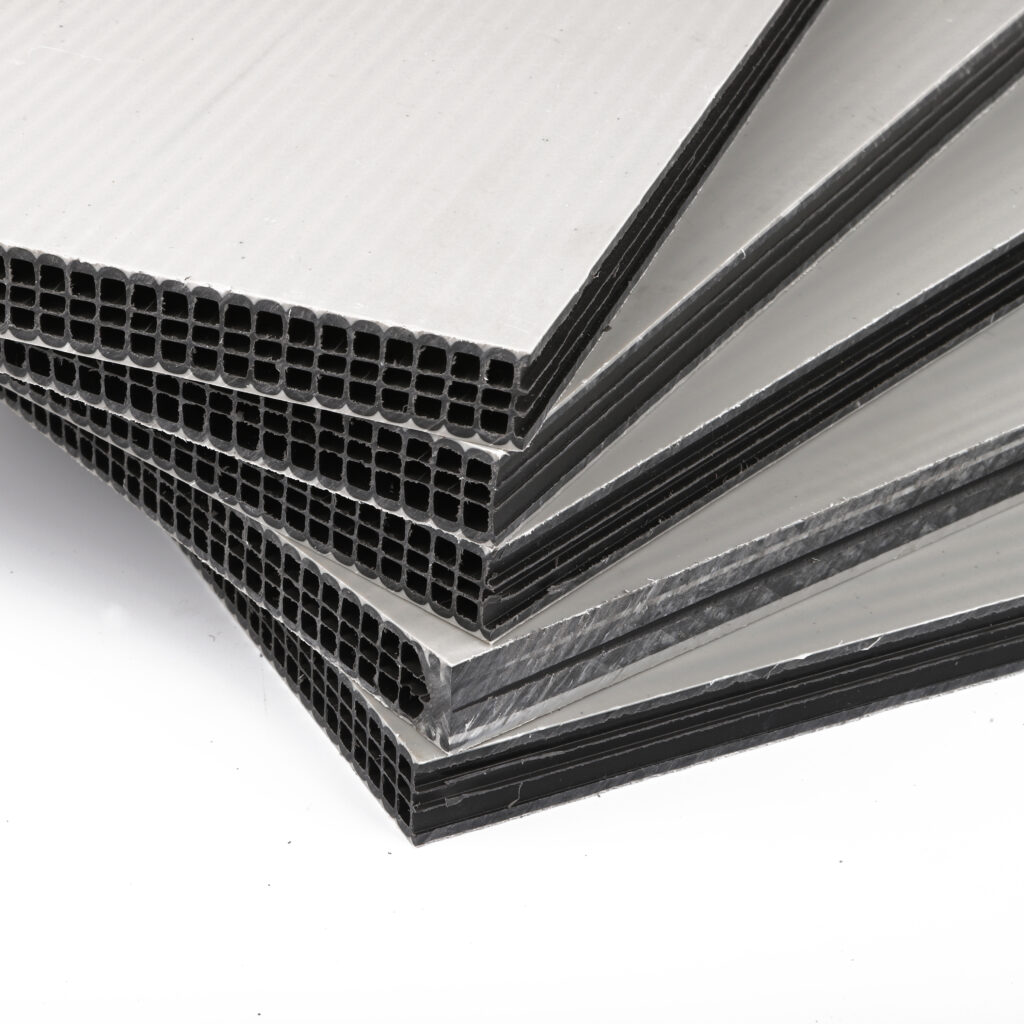

Are you planning a project where you’ll be sawing PVC? Hard PVC sheets and foamed PVC sheets can both be sawn in different ways. You can also cut sheets less than 5 mm thick using a sharp Stanley knife. In this blog, we explain how to saw PVC sheets that are thicker than 5 mm.

To saw PVC, you’ll need:

- Saw

- Masking tape

- A pen or pencil

- Safety glasses

- Glue clamps or locking pliers

- Underlay board

The basics of sawing PVC

You can saw both hard PVC and foamed PVC sheets thicker than 5 mm with different types of saws, such as bandsaws, circular saws, panel saws and jigsaws. The secrets to making a clean cut are to use a high cutting speed (rpm) and to feed the material through smoothly. The saw must have a dust/chip extraction. Be sure to wear safety glasses at all times and mark your cutting line on a piece of masking tape before you start. Here are some handy tips to achieve the best cut using the various types of saws:

# 1. How to saw PVC with a jigsaw

A connection for dust extraction is essential. Use a saw blade suitable for plastics. Set the jigsaw at medium to high speed and move the saw gently through the material. Proper guidance and the support of the sheet with glue clamps or pliers are essential. Prevent the sheet from vibrating during sawing.

# 2. How to saw PVC with a circular saw

When sawing PVC with a circular saw, choose an HSS saw blade with alternating teeth, suitable for plastics. The teeth clearance angle must be between 10 ° to 15 °, the rake angle up to a maximum of 6 °.

# 3. How to saw PVC sheet with a band saw

If you’re going to saw PVC with a band saw, choose a saw blade with fine teeth, pitch approx. 2.5 mm. Maintain a high cutting speed, but ensure the PVC sheet passes smoothly along the saw. It’s also essential to support the sheet well using clamps or locking pliers.