Home ● Plastic Sheets ● Acrylic/PMMA Sheets

Search

Product Order

Everything you need to know choosing Acrylic/ PMMA sheets

Acrylic sheets are well-known and a popular plastic. Acrylic sheets are also known as Arcylic glass, PMMA, and Lucite sheets. Acrylic is the most transparent plastic in the plastics industry. It is the popular and easily available material for creating signs, walls, displays, boxes, stands, glass substitutes, tables, sanitary wares, and safeguards.

Acrylic sheet is widely used as a replacement for glass. In terms of lightweight, transparency, durability, safety, fabrication, acrylic is a more reliable material compared with glass because it is shatterproof against breakage. Acrylic sheets are available in more than 40 colours and 10 different thicknesses. Besides, finishes, and textures are available, which make it always our customers’ favorite choice in their designs and projects throughout the years.

What grades of acrylic sheets are available?

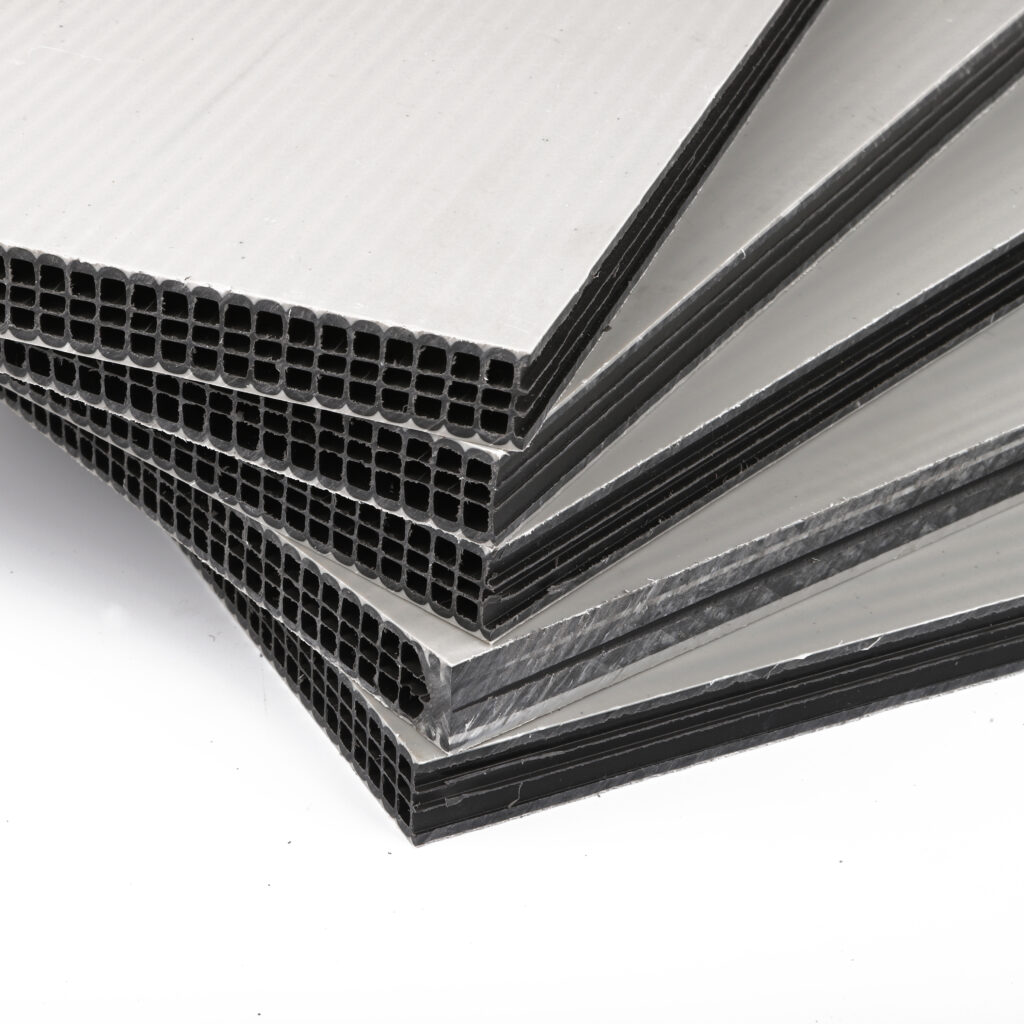

Acrylic sheets are available in two different grades: extruded acrylic sheets and cast acrylic sheets. The difference between these two sheets is due to two different manufacturing processes.

Extruded acrylic sheets

With Extruded acrylic sheets, the liquid material is extruded (pressed) into a sheet. This makes the manufacturing process more efficient and therefore faster. This makes extruded acrylic sheets cheaper. The disadvantage is that the extrusion gives the extruded acrylic sheet a higher internal material stress. This makes extruded acrylic sheets less suitable for self-processing, as extruded acrylic sheets are more likely to crack or break.

Cast acrylic sheets

Cast acrylic sheets are poured into a mould during production. This produces a cast acrylic sheet, which is without internal material stresses. Consequently, this grade is very suitable for self-machining and therefore hardly splinters or cracks in contrast to extruded acrylic sheets.

What applications are acrylic sheets suitable for?

Acrylic sheets are an extremely versatile material. There are an almost infinite number of possible applications.

Protective covers

■ Lighting

■ Machinery

■ Posters

■ Automotive

■ Menu boards

Design

■ Glazing

■ Light fittings

■ Decoration

■ Furniture

■ Interior design projects

Signage

■ Illuminated

■ Non-illuminated

POS & POP displays

■ Store fixtures

■ 3-Dimensional

A range of diverse and unusual applications

■ Sun beds

■ Overhead projectors

■ Picture framing

Available colours and thicknesses

In our wide range you will find acrylic sheets in more than 40 colours and more than 10 thicknesses. You will even find acrylic sheets with a mirror finish.

Thicknesses

The acrylic sheets are available in sheet thicknesses: 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm, 70mm, 80mm, 90mm, and 100mm.

Colours

What machining options are available for acrylic/PMMA sheets?

Machining operations, drilling and sawing are, of course, possible. But acrylic sheets are also suitable for:

Bending (warm)

Drilling

Engraving

Glueing

Lasering

Milling

Painting

Polishing

Sawing (circular saw)

Sawing (jigsaw)

Lettering

Turning

What feature do acrylic/PMMA sheets have?

■ Excellent Diffusion Characteristics

■ Exceptional Light Transmission

■ Maximum LED Hiding Power

■ Soft Subtle Texture

■ Easily Fabricated and Thermoformed

■ Lightweight – Half the Weight of Glass

■ Fingerprint and Mar Resistant Surface

■ Consistent Optical Performance Across All Thicknesses

■ Maintains Same Soft Appearance After Bending & Forming

■ Excellent resistance to weather

■ High surface hardness

■ Smooth and glossy

■ Good processability; it is suitable for both mechanical process and thermal forming;

■ It has good resistance to chemical corrosion and it is suitable for surface decorations such as spaying, silkscreen printing and vacuum evaporation coating.

■ Various applications and designs.

Also known as: Acrylic sheet has many trade names including Perspex Sheet, Plexiglas, Altuglas & Policril, acrylic splashback