Home ● Plastic Sheets ● Extruded Acrylic Sheet

Product Order

Everything you need to know about Extruded acrylic sheet

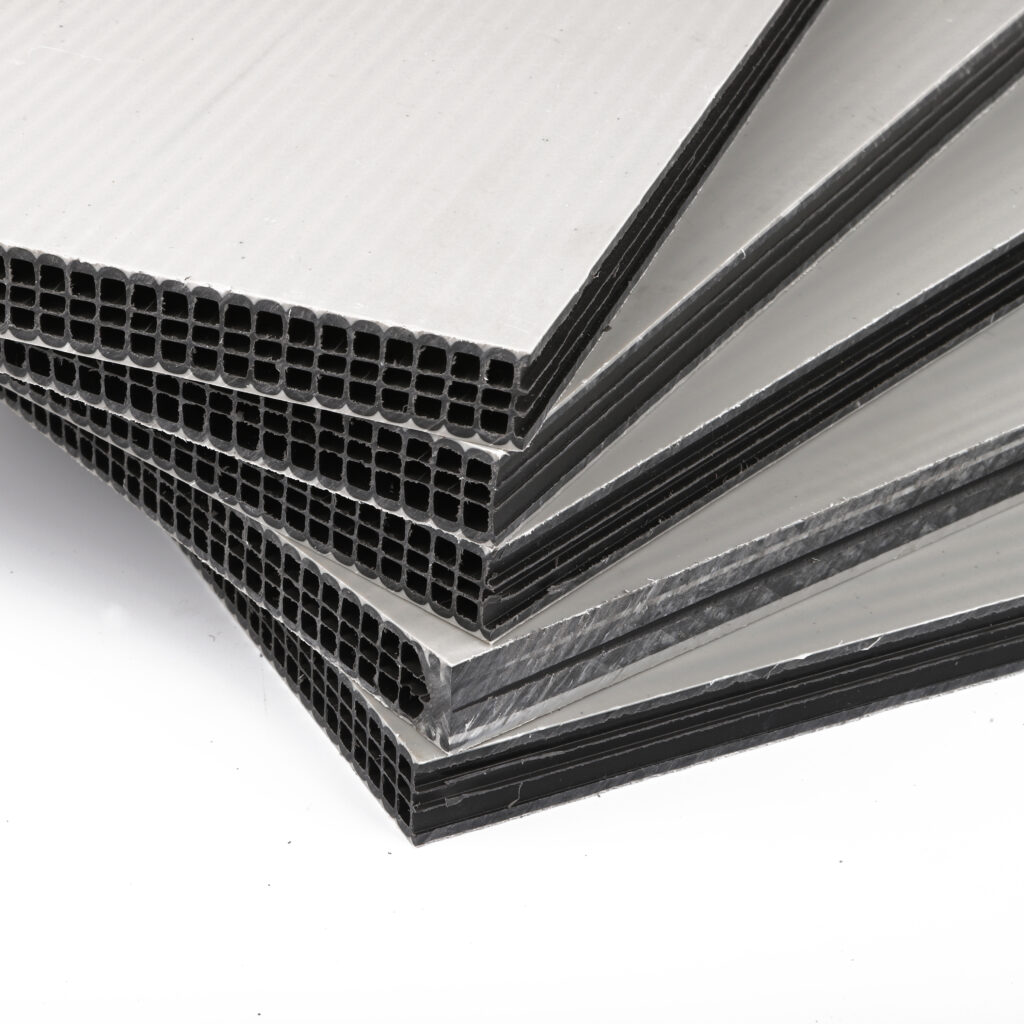

Extrusion is a continuous manufacturing production method where acrylic monomers are first heated then fed through barrels where the chemical process occurs. As a result, extruded acrylic is heterogeneous with properties that may vary depending upon the direction of extrusion.

The technology is PMMA (acrylic) particles as raw materials, extruded through the extrusion line production line, compared with the casting plate, the molecular weight of the extruded plate is low, the mechanical properties are weaker. But easier to bend than the casting plate and vacuum plastic molding, and the length of the plate is not limited, flatness is good, the tolerance is minimal.

Extruded acrylic sheet features an impact-resistant design that is up to three times stronger than double strength window glass and up to five times stronger than wire glass. It’s also nearly half the weight of these glass materials. Why are these features important? It’s because they add up to a reduction in breakage during transit, greatly reduced shipping costs, and longer overall life of the critical parts used in the application.

Extruded acrylic sheet is available in many colors, patterns, and textures and can be ordered in custom sizes and thicknesses.

Extruded acrylic costs less than cast and is more dimensionally stable, meaning the thickness is more consistent across sheets. Softer, with a lower melting temperature than in its cast form, extruded acrylic is easier to laser cut, rout, and polishes more cost-effectively. Scratched glass is a lost cause, but because acrylic, both cast and extruded, can be polished, it is a more durable option for multiple applications. Extruded acrylic is less susceptible to dirt, lint, or particulate contamination in the production process. Additionally, because of its lower melting point, it is better suited to cementing and thermoforming.

Characteristics of Extruded acrylic sheet

■ Impact strength: The impact strength of Acrylic sheets is 17 times that of glass

■ Light weight: The weight of an Acrylic sheet is only about half of a glass.

■ Transparency: The light transmission of Acrylic sheet is 93%(clear) Glass is only 90%

■ Scratch resistance

■ Good chemical resistance, superior to most other plastic materials, Chlorinated water has little or no effect on acrylic, as mineral glass degrades rapidly.

■ Thermo formable

■ Free of any kind of heavy metal or poisonous ingredients

■ Can be milled, polished, routed, cut, bonded, screwed etc

■ Can be easily cold and hot bended, decorated with lamination and printing

■ Resistance to weather: Acrylic sheets have good resistance to bad weather and are not prone to yellowing

Thicknesses

Extruded acrylic sheets are available in sheet thicknesses: 0.8mm, 1mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 15mm, 20mm