HDPE

Everything you need to know about choosing PE (polyethylene) Sheet

Polyethylene (PE), light, versatile synthetic resin made from the polymerization of ethylene. It is the most widely used plastic in the world, being made into products ranging from clear food wrap and shopping bags to detergent bottles and automobile fuel tanks.

It is available in various grades, including high-density polyethylene (HDPE), low-density polyethylene (LDPE).

Low-density polyethylene

LDPE (Low Density Polyethylene), also known as a polyolefin material, is a semi-crystalline thermoplastic material, with a continuous use temperature range of up to 200° F (93° C). It is categorized as a standard material, and offers strong chemical resistance, high flexibility, and low moisture absorption.

LDPE is a water-resistant, cost-efficient, long-lasting, and 100% recyclable multi-purpose material used for a variety of commercial and residential applications. Compared to high-density polyethylene, LDPE is more flexible and lighter in weight, making it an ideal solution for applications that are vacuum- or drape-formed. It exhibits excellent impact resistance, as well as chemical resistance, making it suitable for work surfaces requiring corrosion resistance. Light-transmission options range from translucent to opaque.

High-density polyethylene

What is HDPE? High-density polyethylene (HDPE) is a strong, lightweight, and chemically resistant plastic material popular for a variety of applications. Plus, HDPE plastics are highly impact resistant, making them ideal for toys and products that need to withstand a lot of wear and tear. They also resist mold, mildew, rotting, and insects, making them suitable for many industries such as piping and construction.

What is HDPE plastic used for? HDPE is used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture absorption and chemical- and corrosion-resistance properties are required. Patio furniture, food storage containers, recycled plastic lumber, and trash and recycling bins.

Are HDPE Sheets recycled? HDPE plastic is an excellent choice for those looking for a green and planet-friendly option. HDPE plastic is one of the most easily recyclable materials. By recycling HDPE plastic, businesses and individuals can significantly reduce production costs. It is also especially lightweight and super strong.

Want to find out more about high-density polyethylene (HDPE)? Click Here to learn more!

Properties of PE Sheet

PE sheet has several properties that make it an ideal material for various applications. Some of the essential properties of PE sheet include:

■ Chemical Resistance: PE sheet is resistant to many chemicals, including acids, bases, and solvents. It can withstand exposure to harsh chemicals without degrading or becoming damaged.

■ Weather Resistance: PE sheet is resistant to weather conditions, including sunlight, rain, and snow. It can withstand exposure to UV radiation without breaking down or becoming brittle.

■ Temperature Resistance: PE sheet can withstand a wide range of temperatures, from -50°C to 80°C. It can maintain its physical properties even at extreme temperatures.

■ Moisture Resistance: PE sheet is resistant to moisture and can be used in wet environments without becoming damaged.

■ Electrical Insulation: PE sheet is an excellent electrical insulator and can be used in electrical applications.

Advantages of PE Sheet

PE sheet has several advantages that make it a popular choice for various applications. Some of the advantages of PE sheets include:

■ Cost-effective: PE sheet is a cost-effective material that is cheaper than many other plastic materials.

■ Lightweight: PE sheet is a lightweight material that can be easily transported and handled.

■ Recyclable: PE sheet is recyclable and can be reused multiple times.

■ Versatile: PE sheet is a versatile material that can be used in various applications.

■ Durable: PE sheet is a durable material that can withstand exposure to harsh environments.

Applications of PE Sheet

■ Aquaculture

■ Wastewater Treatment

■ Biopharmaceutical

■ Food Processing

■ Guides & Wear Plates

■ Dunnage / Racking

■ Chemical & Liquid – Tanks & Secondary Containment

■ Medical – Orthotics & Prosthetics

■ Material Handling Systems

■ Machined & Fabricated Parts

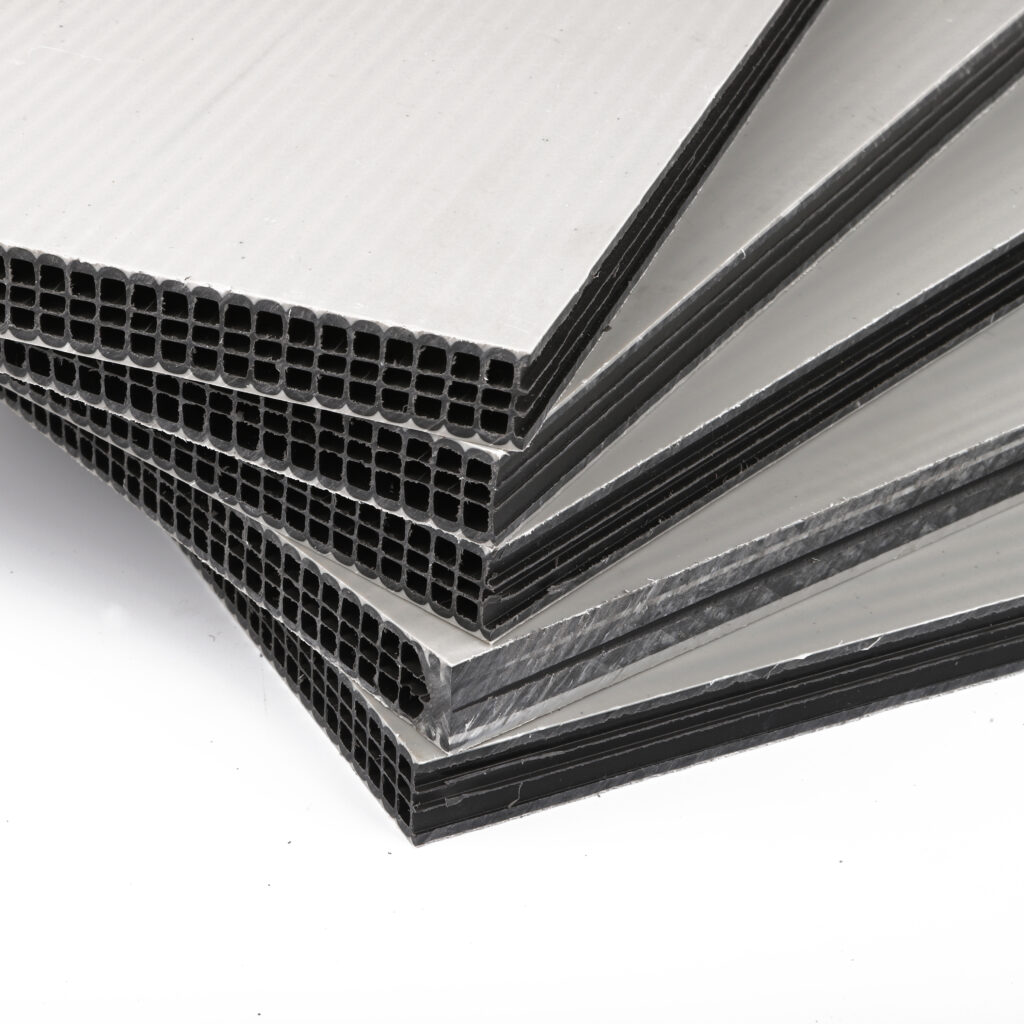

Variants and colours

Colours

We supply PE sheet material in Natural natural color, black.

Thicknesses

You have a choice of different sheet thicknesses, ranging from 3 to 75 millimeters.

Natural: 3mm- 75mm

Black: 3mm- 25mm

Finish

Smooth or Matte