Everything You Need To Know Choosing PVC Celuka Foam Sheets

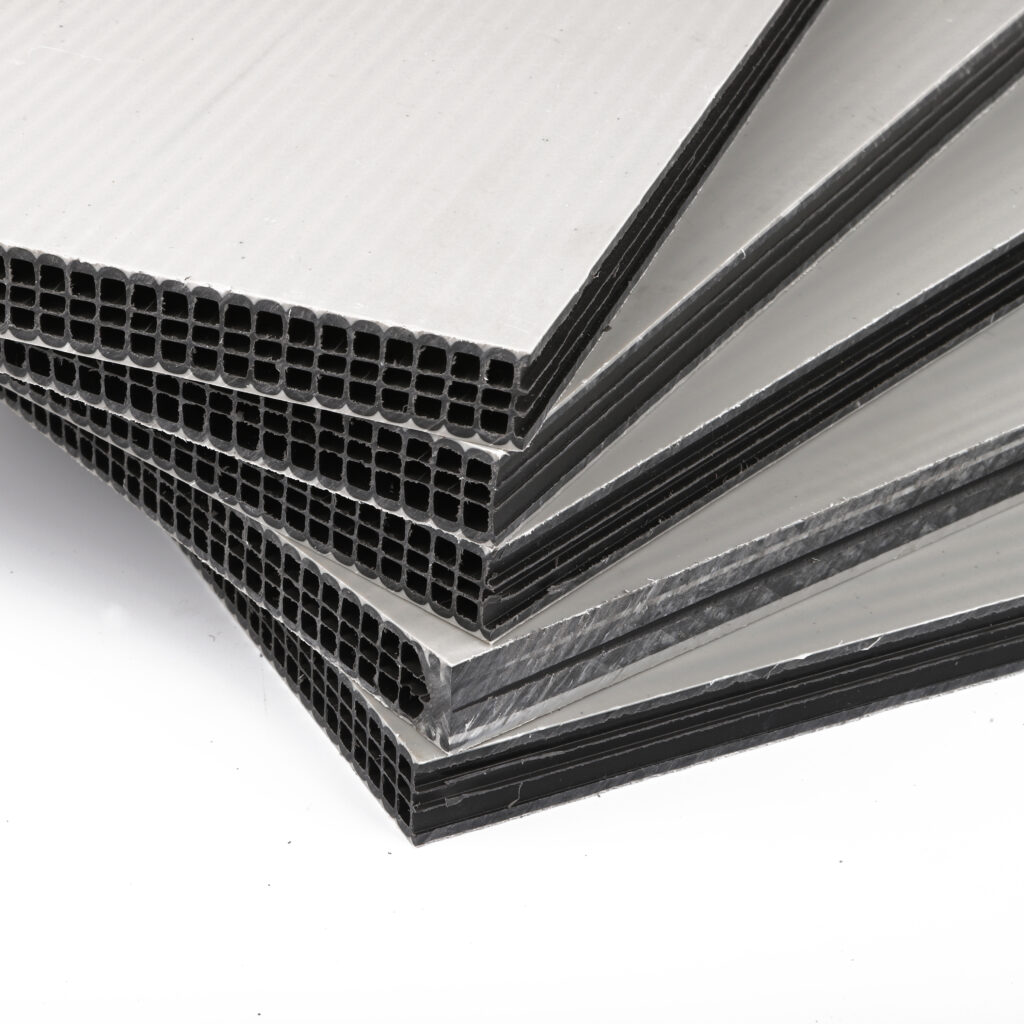

“Celuka” is one of the production processes. the Celuka method uses a mandrel inside the mold and there is usually little space between the mold and the calibrator. The cooling of the surface in contact with the calibrator wall produces a very strong skin on the surface of the board while filling the foam layer inside.

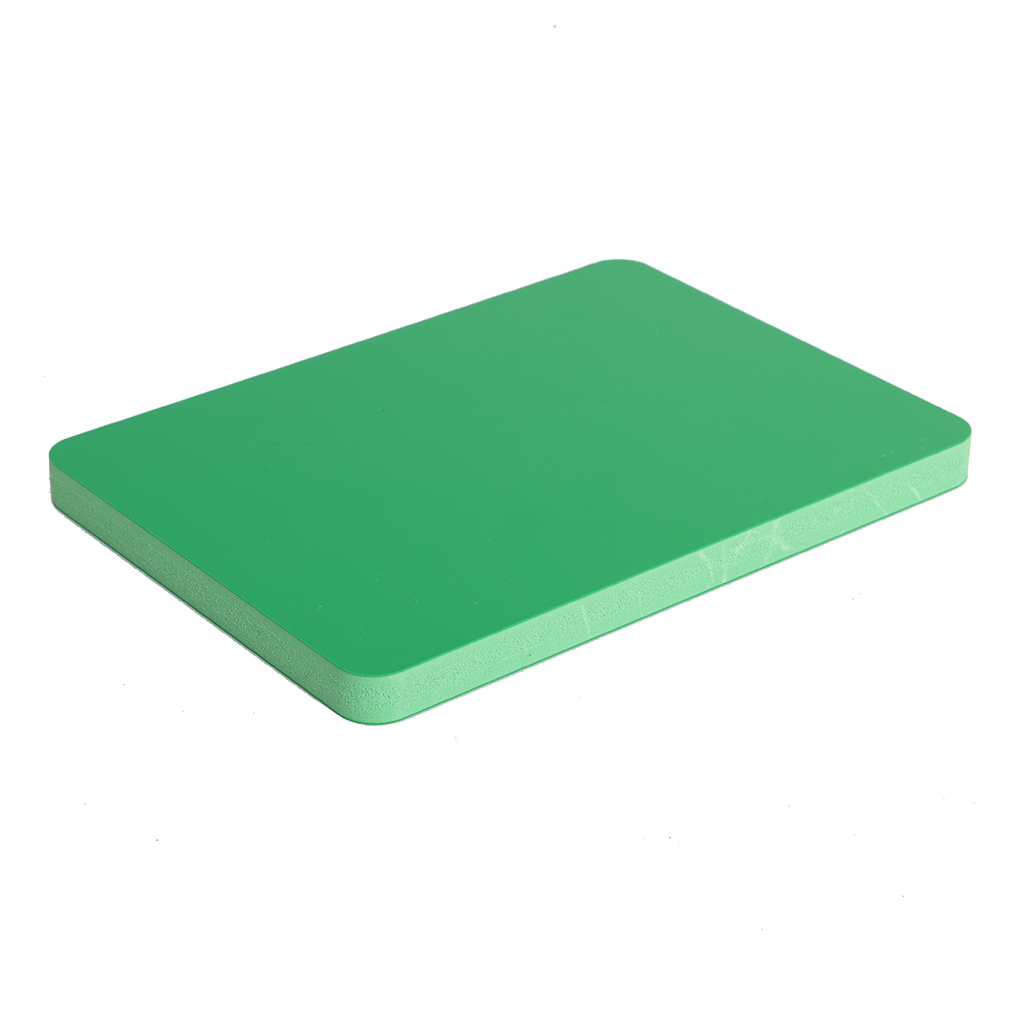

Celuka PVC Foam is a rigid expanded foamed PVC sheet with a smooth gloss hardened finish on both sides. It is also often referred to and known as Rigid PVC Foam Sheet. Celuka Foamed PVC / Rigid PVC foam sheets can be easily painted, printed and fabricated and are available in different thicknesses and colours.

Celuka Foamed PVC Sheet has a light weight cellular structure making it easy to handle and fabricate.

Like other Foamed PVC sheet, Celuka is ideal for model making, building and construction as well as trade shows and exhibitions, thanks to its weight and easy of fabrication.

Characteristics and Benefits

■ We is the substrate of choice when the following characteristics are required:

■ Fine-cell foam structure – light and easy to fabricate

■ Smooth outer skin – ideal for screen printing, paints and vinyls

■ Gloss finish – high-tech look

■ Homogeneous coloring – little change in color from run to run

■ Widest range of thicknesses – 4 – 30 mm

■ Great for indoor and outdoor uses

■ Thermal and sound insulation – absorbs vibrations and oscillations

■ Good insulation value

■ High lexural strength

■ High impact strength – suitable for high-traffic areas

■ Lighteight and easy to handle

■ Easy to fabricate with most common tools

■ Weatherproof and light-fast – solid surface ideal for exterior applications where other products have failed

■ Chemical and corrosion resistance

■ Moisture resistance – low water absorption

■ Low flammability – perfect for trade shows and exhibit halls

■ Bonds easily to similar and various other substrates

Trade information for PVC Celuka Foam Sheets

Advertising technicians

Digital printers

Design & advertising agencies

Exhibition stand builders

POS fitters

Sign makers

Interior decorators

Cabinet makers

Window manufacturers

Fitters

Roller-shutter manufacturers

Conservatory manufacturers

Product range

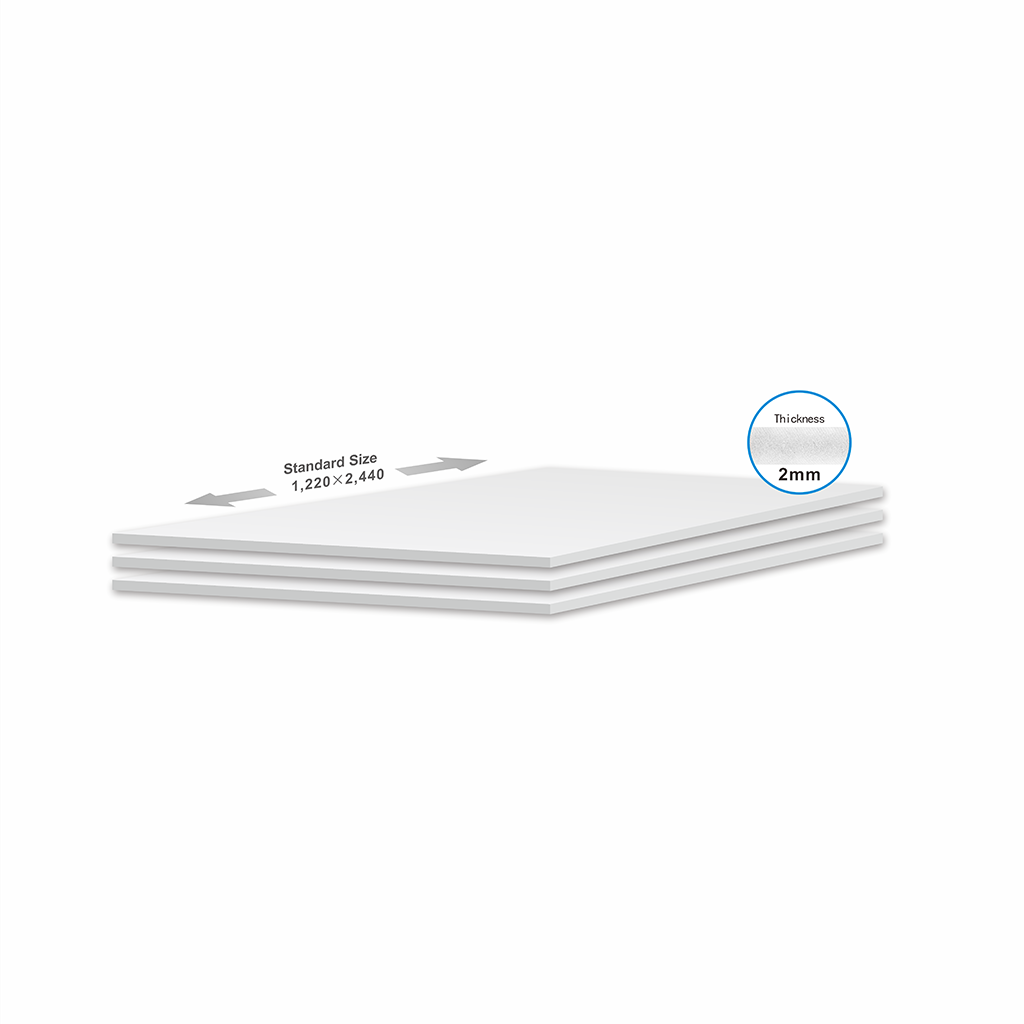

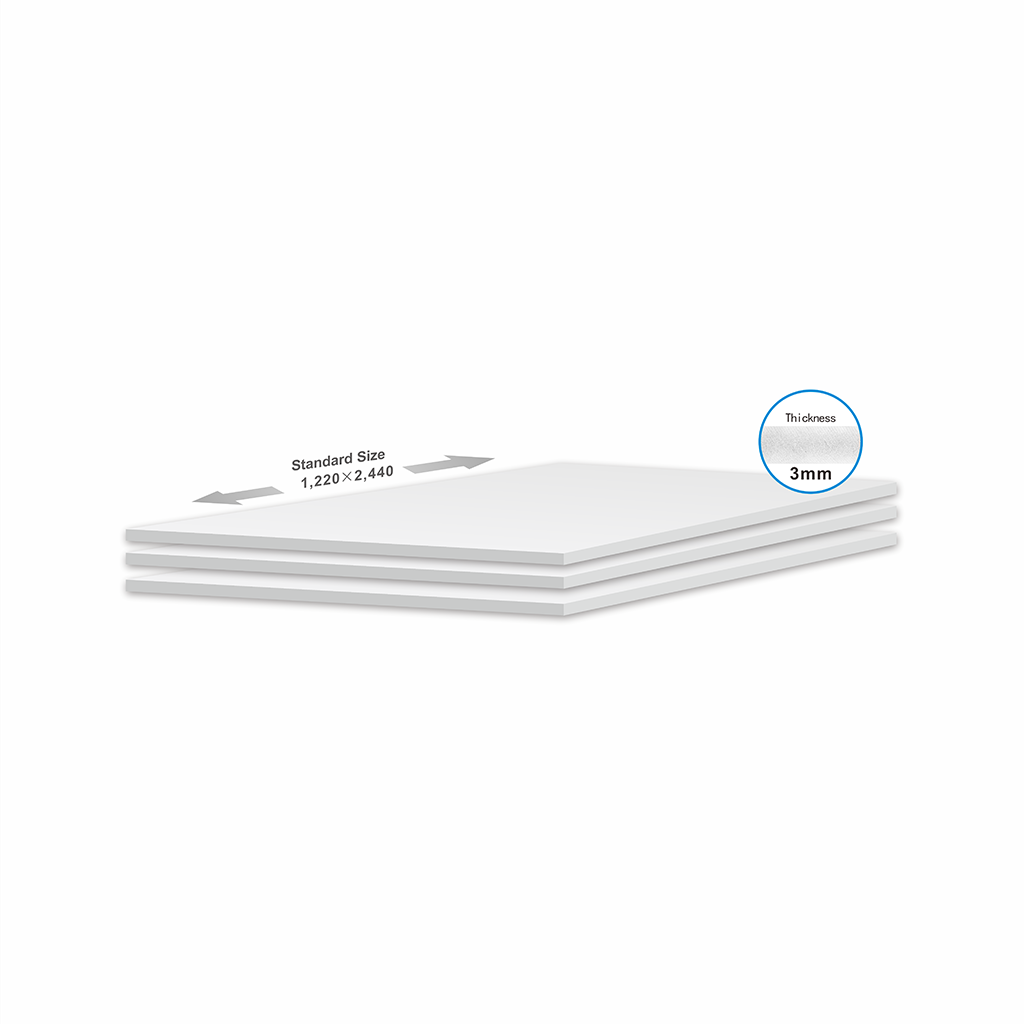

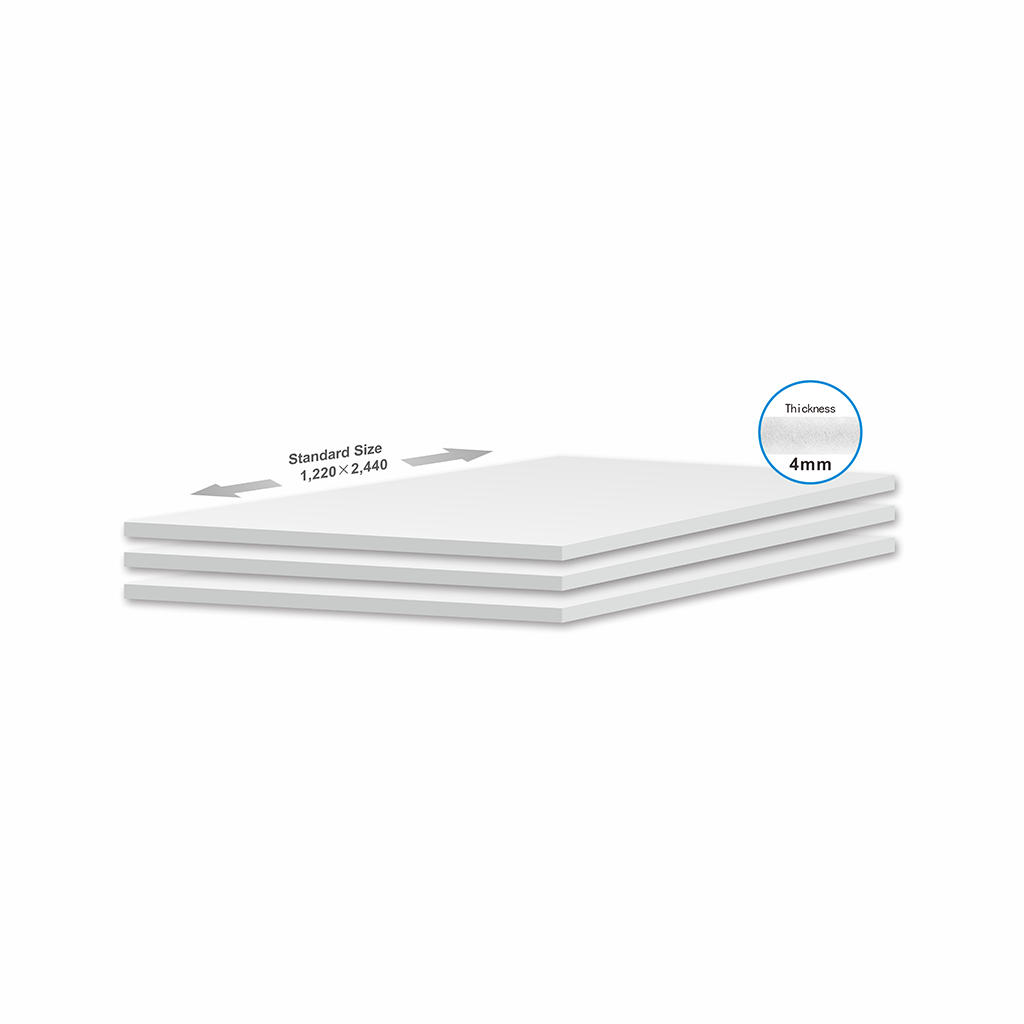

The choice is yours: standard sheets are available in five different sizes.

Extruded sheets (size/thickness in mm)

| SHEET | Length & Width | Density | Surface | |||

| Thickness | 2,440 x 1,220 | 3,050 x 1,220 | 3,050 x 1,560 | 3,050 x 2,050 | 0.35-0.8g/cm3 | Glossy, Matt, Texture, Embossed, Laminated |

| 1-30mm | ■ | ■ | ||||

| 2-20mm | ■ | |||||

| 2-18mm | ■ | |||||

Thicknesses

In addition to the different colours, you have a choice of different sheet thicknesses, ranging from 1 to 30 millimetres.

Features of PVC Celuka Foam Sheets

Weatherproof and weather resistant

Very good for bonding

Thermoformable

Uniformly and finely structured surface

Simple processing

Uniformly and finely structured surface

Low thermal conductivity

Lightweight

Ideal for punching work

Good surface strength

Flame resistant

Good for laminating

Excellent printing quality

Chemical and corrosion resistant

Fine-celled foam structure

Digital Printing

Dimensional Lettering

Displays

Exhibition and Showroom Stands

Inscription Panels

Photo Lamination

Screen Printing

Shop Window Decorations

Signs

3D models

decorative partition walls

wall cladding

indoor or outdoor decoration

air conditioning ducts, windows

indoor or outdoor decoration

false ceilings/walls

waterproof cladding

trim, baseboard

window or door molding

wall cladding

cabinets

architectural panels

wall structures for corrosive environments

ducts

Colored PVC celuka Foam Board

PVC Celuka colored foam sheet is a kind of PVC Foam Board, which is manufactured by celuka foaming machine. Its main ingredients include PVC resin and special additives like foaming agent, anti-aging agent, colorant. etc.

Our company mainly produces: red pvc board, blue pvc board, white pvc board, green pvc board, black pvc board and other color pvc boards and foam boards.

The sheet has a flat glossy surface and excellent face hardness. Because of its coating-free and water-proof character, it is widely applicable to indoor and outdoor decoration.

Coloured:

White

Black

Yellow

Green

Processing options

PVC sheets are easy to process. We are happy to explain the various processing options for foamed and hard PVC.

Process foamed PVC (foam sheet)

Foamed PVC can be sawn, cut, drilled, painted and bent. The surface is flat and smooth and can be printed and inscribed very well.

Working with hard PVC

Hard PVC is very easy to machine with machining techniques such as sawing, drilling, milling. Hard PVC can be bent easily using heat (filament).

Cutting

Drilling

Sawing

Sawing (jigsaw)

Sawing (circular saw)

Glueing

Bending (warm)

Painting

Nailing