Everything you need to know about when choosing hard PVC sheets

PVC solid sheets are a durable, tough material that is resistant to chemicals, acids, weather and abrasion. It can be machined and tooled into a vast variety of shapes and components. It is strong yet relatively lightweight, affordable and widely available. While it has a low melting point in comparison to other plastics, this is a great advantage to fabricators. It has a very good fire rating as its self-extinguishing.

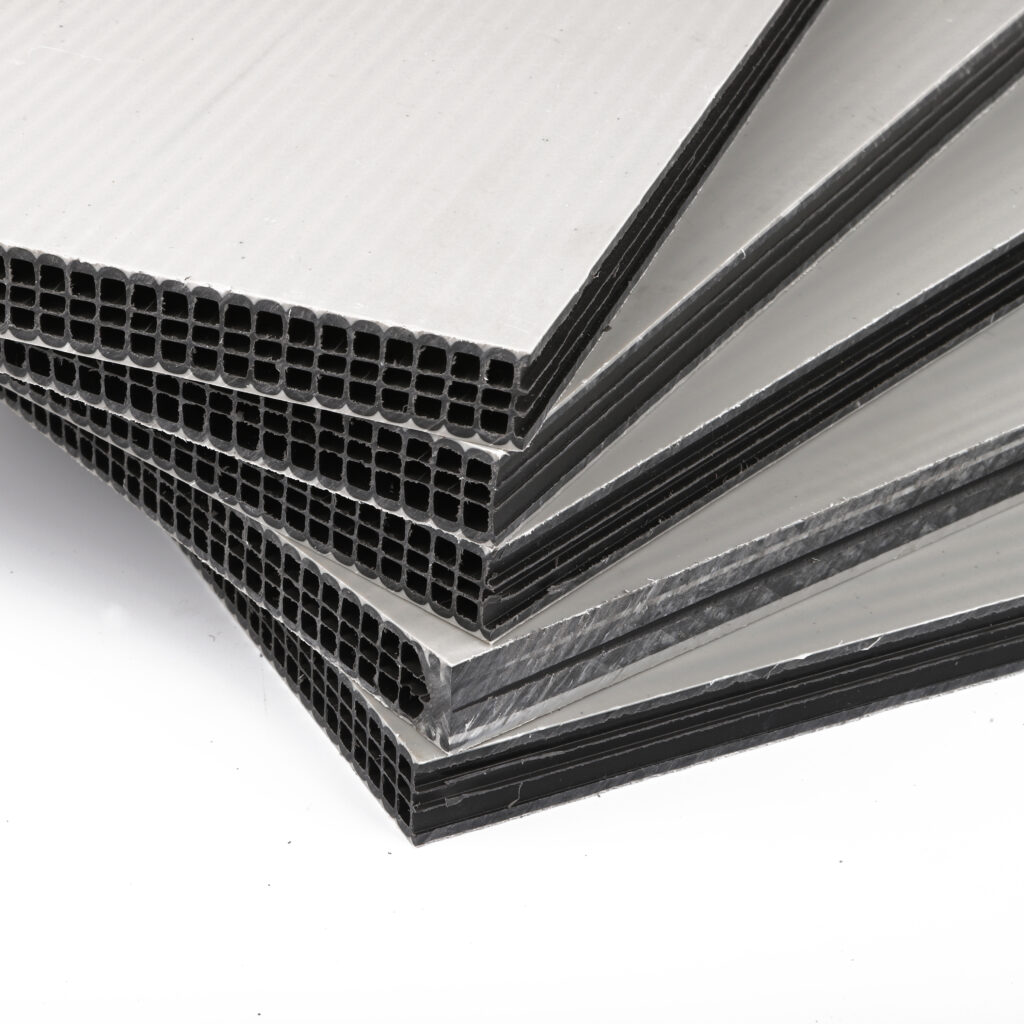

Hard PVC sheets are relatively heavy compared to foamed PVC sheets. PVC foam sheets are as much as 50% lighter. Hard PVC is solid and easy to process by drilling, sawing, welding and milling. We supply hard PVC plates in the colors white and dark grey. The hard PVC plates are available in various thicknesses.

Advantages of the rigid PVC Sheets

■ Hard PVC has good hardness and mechanical properties.

■ Good electrical insulating properties

■ Very high chemical & moisture resistance

■ Excellent forming characteristics

■ Good dimensional stability

■ Bondable and excellent for welding

■ Hard PVC sheets and rods are self-extinguishing

■ Fairly inexpensive

Disadvantages of PVC Sheets

■ Heat stability of PVC isn’t great– when the temperature reaches 140 °C PVC starts to decompose and its melting temperature is 160 °C.

■ Its electrical insulating property isn’t quite as good as plastics such as polyethylene and polypropylene.

■ PVC should not be used for items requiring a lot of flexibility, low friction, high wear resistance

■ Generally PVC is only suitable for medium or low voltage and low frequency insulation materials.

■ PVC sheets and rods should be used for continuous contact with food products.

Characteristics

Rigid plastic sheets are chemical and heat resistant (up to 70°C). It is a great electrical insulator, pressure resistant and easy to process. It is also extremely fire resistant, and said to be self-extinguishing. Hard PVC is also resistant to chemicals, which makes it an ideal material for making drip pans or sinks for chemicals. In addition, solid PVC cannot be easily broken, so it is also vandal resistant.

PVC products have a long service life; polyvinyl chloride pipes have a service life of at least 100 years. The great advantage of PVC is that it is easy to recycle. At the end of its life, PVC can easily be shredded into granules, which serves as the basis for new PVC products.

Applications of solid PVC sheets

Hard PVC is widely used in the advertising industry. For example, the sheets are used for displays, billboards and stand material. Hard PVC sheets are also popular in the chemical industry, mechanical engineering and electrical engineering. Also consider applications such as insulation, filling strips and electrical boxes.

Types of rigid PVC

Rigid PVC sheets are available in the colours white, dark grey and transparent. We offer the sheets in a range of thicknesses from 2 mm to 20 mm.

Processing rigid plastic sheets

Solid PVC is strong and easy to work with. It can be drilled, cut, stained, painted, lettered, milled, welded, turned and glued with a special PVC adhesive. In addition, this type of sheet can be hot-formed and sawn with a circular saw or a jigsaw.

Drilling

Glueing

Milling

Sawing

Sawing (circular saw)

Sawing (jigsaw)

Bending (warm)

Cutting

Water cutting

Lettering

Turning