Everything you need to know about choosing clear acrylic/PMMA sheet

Clear acrylic sheet is not only just as clear but also 2 x as light and 30 x as strong as ordinary glass, which is why it is often used as a replacement.

Types of clear acrylic/PMMA

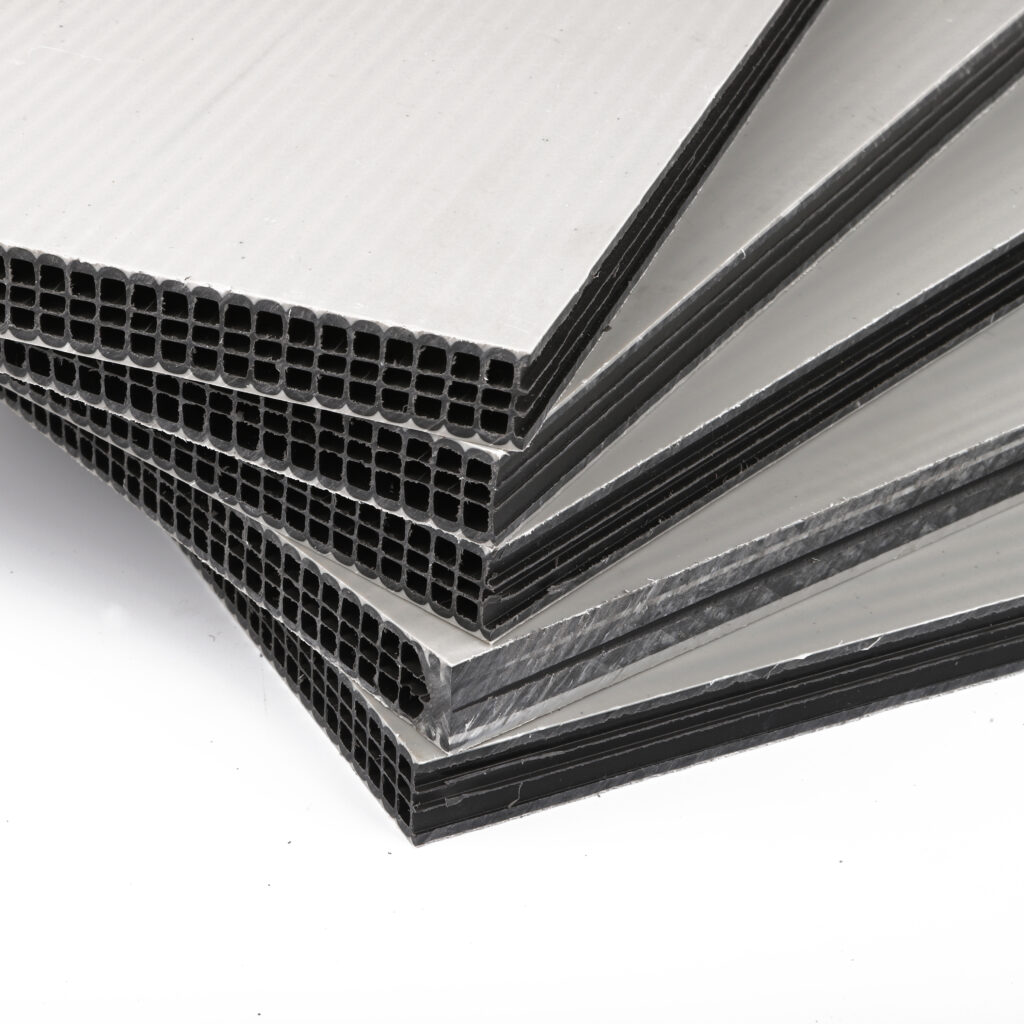

We have two types of acrylic sheets: moulded (cast) and budget (extruded) acrylic. The difference between the two types of acrylic occurs during production. The liquid acrylic is poured into a mould. In the case of budget acrylic sheet, it is then rolled to a thinner sheet thickness. In this way, a relatively large sheet surface can be made with less raw material. This ensures a very favourable price-quality ratio and that’s why we also call this type of acrylic budget acrylic.

Characteristics of clear cast acrylic sheets

Clear Cast is formed by casting acrylic resin into a flat mould which gives it the advantages of a very consistent mechanical structure, a hard surface and great thermal stability. These benefits make it a versatile material suitable for indoor and outdoor applications. It offers high-impact resistance and fantastic optical clarity.

Additionally, Clear Cast Acrylic Sheet is ideal for complex machining processes and it can be easily and cost-effectively fabricated. The casting process makes it less uniform in thickness than extruded materials, with a maximum variation of +/-10% across a sheet.

Clear Cast Acrylic Sheet offers the best optical clarity and is often the acrylic of choice for high-quality display products that require machining.

Key Features of Cast Acrylic Sheet:

■ Optically clearer than glass

■ Suitable for indoor and outdoor use

■ High impact resistance

■ Uniform thickness

■ Suitable for laser cutting

■ Strong and lightweight

■ Up to 92% light transmission – higher than most traditional types of glass.

■ Supplied with protective film on both sides

Characteristics of clear extruded acrylic sheets

We can supply extruded clear acrylic sheets. The sheets leave the factory at a standard size of 1,220 by 2,440 millimeters. Extruded acrylic sheets are processed by rolling several times to achieve the desired final thickness. And though this method requires less raw material, it does increase the internal tension within the sheet. The internal tension makes extruded acrylic sheets more prone to break when it’s being worked. We therefore recommend cast acrylic sheeting if you intend to alter the surface.

As a cheaper alternative to cast acrylic, extruded acrylic sheet is lightweight, impact-resistant and easy to work with.

We offer clear acrylic sheets in various thicknesses from 1mm to 20mm.

Key Features of Clear Extruded Acrylic:

■ Uniform thickness and smooth finish

■ Lightweight and impact-resistant

■ Strong and durable

■ Chemical resistant

■ Low moisture absorption rate

■ UV resistant

■ Better impact resistance than glass

■ Up to 92% light transmission – higher than most traditional types of glass

■ Easy to clean

■ Sheet manufacturing process: Extruded

■ Suitable for laser cutting

■ Suitable for writing with whiteboard marker pens

■ Supplied with protective film on both sides

Working with clear Acrylic sheets

Moulded acrylic is easier to process than budget acrylic. The budget sheets are more stressed and are therefore more liable to crack during processing. Machining is possible, but be extra careful. Better still, opt for the greater strength of a moulded acrylic sheet. These sheets are suitable for processes such as lettering, drilling, (hot) bending, turning, milling, engraving, lasering, glueing, polishing, painting, cutting and sawing with a circular or jigsaw.

Bending (warm)

Drilling

Engraving

Lasering

Glueing

Milling

Painting

Polishing

Sawing (circular saw)

Sawing (jigsaw)

Lettering