Plastic Properties Table

Find the plastic material suited for your application

Discover the comprehensive Plastic Properties Table, your ultimate guide to understanding the characteristics of various plastics. Explore detailed data on material properties such as density, tensile strength, and chemical resistance. Essential for making informed decisions in material selection and design.

Plastic Properties Table features and directions:

View plastic materials found under a specific property group

Find more information about a specific plastic material:

Read property descriptions

What is “tensile strength”, “izod impact”, or “coefficient of friction”? Mouse over a property heading or view a list of Plastic Properties Descriptions.

Typical of Plastic Properties Table

| Materials | Tensile Strength73°F | Flexural Modulus of Elasticity73°F | Izod Impact(notched)73°F | Heat Deflection Temperature°F 66psi / 264psi | Water Absorption Immersion 24 hours |

| Units | psi | psi | ft-lbs/in of notch | °F | % |

| ASTM Test | D638 | D790 | D256 | D648 | D570 |

| Polycarbonate | 9,500 | 345,000 | 12.0 - 16.0 | 280 / 270 | 0.15 |

| PETG | 7,700 | 310,000 | 1.7 | 164 / 157 | 0.2 |

| ECTFE | 7,500 - 8,300 | 232,000 - 261,000 | no break | 195 / 160 | <0.10 |

| PVC | 7,500 | 481,000 | 1 | - / 158 | 0.06 |

| ETFE | 6,100 | 145,000 | no break | - | 0.007 |

| Engravable Sheet | 5500 | - | 1.1 | 175 | - |

| Polypropylene | 5,400 | 225,000 | 1.2 | 210 / - | slight |

| PCTFE | 4,860 - 5,710 | 200,000 - 243,000 | 2.5 - 3.5 | 259 / - | 0 |

| FEP | 4,350 | 95,000 | no break | - | <0.01 |

| ABS | 4,100 | 304,000 | 7.7 | 200 / 177 | 0.3 |

| HDPE | 4,000 | 200,000 | - | 172 / - | 0.1 |

| EVA | 3,580 | 2,470 | - | - | - |

| High Impact Polystyrene | 3,500 | 310,000 | 2.8 | - / 196 | - |

| UHMW | 3,100 | 110,000 | * | - | slight |

| PEEK | 14,000 | 590,000 | 1.6 | - / 306 | 0.5 |

| PPS | 12,500 | 600,000 | 0.5 | 400 / 200 | 0.02 |

| PET | 11,500 | 400,000 | 0.7 | 240 / 175 | 0.1 |

| Acetal | 10,000 | 420,000 | 1.5 | 336 / 257 | 0.25 |

| Acrylic | 10,000 | 480,000 | 0.4 | - / 195 | 0.2 |

| Expanded PVC | 1,975 - 2,900 | 165,000 | 0.7 | - / 181 | 0.15 - 0.30 |

| TPE | 1,740 | - | - | - | - |

| PTFE | 1,500 - 3,000 | 72,000 | 3.5 | 250 / - | <0.01 |

| LDPE | 1,400 | 30,000 | no break | 122 / - | 0.1 |

| Paper Boards | - | - | - | - | - |

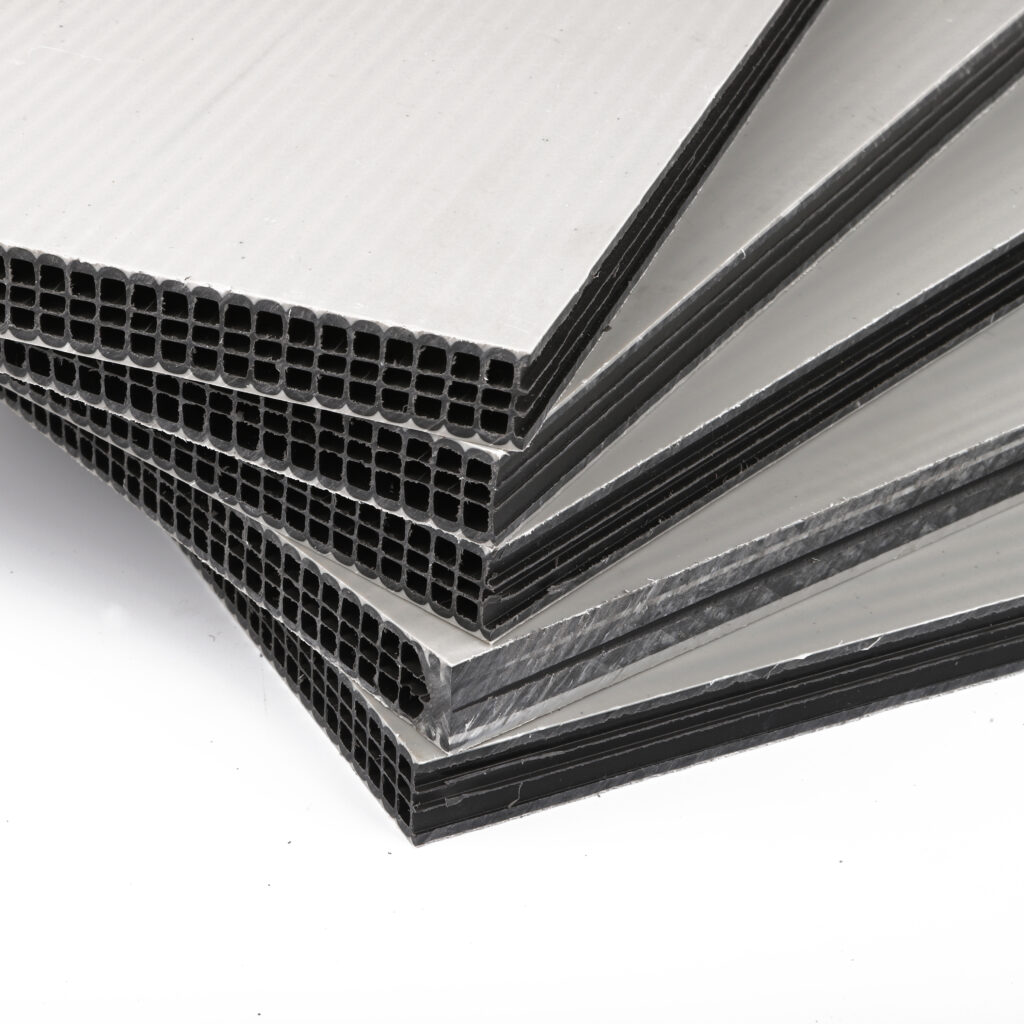

| Fluted Polypropylene Boards | - | - | - | - | - |

| Foam Boards | - | - | - | - | - |

| Polycarbonate Film | * | 330,000 | - | 288 / 270 | 0.35 |

| Polyester Film | * | - | - | - | 0.4 |

Physical of Plastic Properties Table

| Materials | Specific Gravity 73°F | Water Absorption Immersion 24 hours |

| Units | % | |

| ASTM Test | D792 | D570 |

| Polycarbonate | 1.2 | 0.15 |

| PETG | 1.27 | 0.2 |

| ECTFE | 1.68 | <0.10 |

| PVC | 1.42 | 0.06 |

| ETFE | 1.7 | 0.007 |

| Engravable Sheet | - | - |

| Polypropylene | 0.91 | slight |

| PCTFE | 2.11 - 2.17 | 0 |

| FEP | 2.12 - 2.17 | <0.01 |

| ABS | 1.04 | 0.3 |

| HDPE | 0.96 | 0.1 |

| EVA | - | - |

| High Impact Polystyrene | 1.04 | - |

| UHMW | 0.93 | slight |

| PEEK | 1.32 | 0.5 |

| PPS | 1.35 | 0.02 |

| PET | 1.38 | 0.1 |

| Acetal | 1.42 | 0.25 |

| Acrylic | 1.19 | 0.2 |

| Expanded PVC | - | 0.15 - 0.30 |

| TPE | 0.95 | - |

| PTFE | 2.15 | <0.01 |

| LDPE | 0.92 | 0.1 |

| Paper Boards | - | - |

| Fluted Polypropylene Boards | - | - |

| Foam Boards | - | - |

| Polycarbonate Film | 1.2 | 0.35 |

| Polyester Film | 1.39 | 0.4 |

Mechanical of Plastic Properties Table

| Materials | Tensile Strength 73°F | Tensile Modulus of Elasticity 73°F | Tensile Elongation 73°F | Flexural Strength 73°F | Flexural Modulus of Elasticity 73°F | Compressive Strength 10% Deformation 73°F | Hardness Rockwell M&R, Durometer Shore D 73°F | Izod Impact (notched) 73°F |

| Units | psi | psi | % | psi | psi | psi | scale as noted | ft-lbs/in of notch |

| ASTM Test | D638 | D638 | D638 | D790 | D790 | D695 | D785, D2240 | D256 |

| Polycarbonate | 9,500 | 345,000 | 135 | 13,500 | 345,000 | 12,500 | M70, R118, Shore D 80 | 12.0 - 16.0 |

| PETG | 7,700 | 320,000 | 210 | 11,200 | 310,000 | - | R115 | 1.7 |

| ECTFE | 7,500 - 8,300 | 203,000 - 304,000 | 250 - 300 | 6,500 - 8,000 | 232,000 - 261,000 | - | Shore D 73 | no break |

| PVC | 7,500 | 411,000 | - | 12,800 | 481,000 | - | R115, Shore D 89 | 1 |

| ETFE | 6,100 | - | 300 | - | 145,000 | - | Shore D 67 | no break |

| Engravable Sheet | 5500 | - | - | - | - | - | M45 | 1.1 |

| Polypropylene | 5,400 | - | - | - | 225,000 | - | Shore D 75 | 1.2 |

| PCTFE | 4,860 - 5,710 | - | 100 - 250 | 9,570 - 10,300 | 200,000 - 243,000 | - | Shore D 90 | 2.5 - 3.5 |

| FEP | 4,350 | - | 300 - 325 | - | 95,000 | - | Shore D 55 | no break |

| ABS | 4,100 | 294,000 | 32 | 9,100 | 304,000 | - | R102 | 7.7 |

| HDPE | 4,000 | - | 600 | - | 200,000 | - | Shore D 69 | - |

| EVA | 3,580 | - | 770 | - | 2,470 | - | - | - |

| High Impact Polystyrene | 3,500 | 270,000 | 52 | 7,000 | 310,000 | - | M75 | 2.8 |

| UHMW | 3,100 | - | 350 | - | 110,000 | - | Shore D 64 | * |

| PEEK | 14,000 | 490,000 | 60 | 24,600 | 590,000 | - | M105, R126, Shore D 85 | 1.6 |

| PPS | 12,500 | 480,000 | 4 | 21,000 | 600,000 | - | M95, R125, Shore D 85 | 0.5 |

| PET | 11,500 | 400,000 | 70 | 15,000 | 400,000 | - | M93, R125, Shore D 87 | 0.7 |

| Acetal | 10,000 | 450,000 | 75 | 14,300 | 420,000 | - | M89, R121, Shore D 83 | 1.5 |

| Acrylic | 10,000 | 400,000 | 4.5 | 17,000 | 480,000 | 17,000 | M95 | 0.4 |

| Expanded PVC | 1,975 - 2,900 | - | - | 3,755 | 165,000 | - | Shore D 55 | 0.7 |

| TPE | 1,740 | - | 31 | - | - | - | - | - |

| PTFE | 1,500 - 3,000 | - | 100 - 200 | - | 72,000 | - | Shore D 55 | 3.5 |

| LDPE | 1,400 | - | 500 | - | 30,000 | - | Shore D 55 | no break |

| Paper Boards | - | - | - | - | - | - | - | - |

| Fluted Polypropylene Boards | - | - | - | - | - | - | R75 | - |

| Foam Boards | - | - | - | - | - | - | - | - |

| Polycarbonate Film | * | * | * | - | 330,000 | - | M70, R118 | - |

| Polyester Film | * | * | * | - | - | - | 1.5 | - |

Thermal of Plastic Properties Table

| Materials | Coefficient of Linear Thermal Expansion | Heat Deflection Temperature | Max Continuous Service Temperature In Air |

| Units | in/in/°F x 10-5 | °F | °F |

| ASTM Test | D696 | D648 | |

| Polycarbonate | 3.8 | 280 / 270 | 240 |

| PETG | 3.8 | 164 / 157 | - |

| ECTFE | 5 | 195 / 160 | 302 |

| PVC | 3.2 | - / 158 | 140 |

| ETFE | 7.4 | - | 311 |

| Engravable Sheet | 5.6 | 175 | - |

| Polypropylene | 5 | 210 / - | 180 |

| PCTFE | 3.9 | 259 / - | 380 |

| FEP | 7.5 | - | 392 |

| ABS | 5.6 | 200 / 177 | 160 |

| HDPE | 9 | 172 / - | 170 |

| EVA | - | - | - |

| High Impact Polystyrene | 4.5 | - / 196 | - |

| UHMW | 11.1 | - | 180 |

| PEEK | 2.6 | - / 306 | 480 |

| PPS | 4 | 400 / 200 | 338 |

| PET | 3.9 | 240 / 175 | 230 |

| Acetal | 6.8 | 336 / 257 | 212 |

| Acrylic | 4 | - / 195 | 160 |

| Expanded PVC | 2.3 | - / 181 | - |

| TPE | - | - | - |

| PTFE | 8.9 | 250 / - | 500 |

| LDPE | - | 122 / - | - |

| Paper Boards | - | - | - |

| Fluted Polypropylene Boards | - | - | - |

| Foam Boards | - | - | - |

| Polycarbonate Film | 3.9 | 288 / 270 | - |

| Polyester Film | 0.9 | - | - |

Electrical of Plastic Properties Table

| Materials | Dielectric Strength |

| Units | V/mil |

| ASTM Test | D149 |

| Polycarbonate | 380 |

| PETG | 410 |

| ECTFE | 385 |

| PVC | 544 |

| ETFE | * |

| Engravable Sheet | - |

| Polypropylene | - |

| PCTFE | 500 |

| FEP | 500 |

| ABS | - |

| HDPE | - |

| EVA | - |

| High Impact Polystyrene | - |

| UHMW | - |

| PEEK | 480 |

| PPS | 450 |

| PET | 400 |

| Acetal | 500 |

| Acrylic | 430 |

| Expanded PVC | - |

| TPE | 889 |

| PTFE | 400 - 500 |

| LDPE | - |

| Paper Boards | - |

| Fluted Polypropylene Boards | - |

| Foam Boards | - |

| Polycarbonate Film | - |

| Polyester Film | - |

Optical of Plastic Properties Table

| Materials | Light Transmittance Transparency / Clarity | Haze Cloudy Appearance |

| Units | % | % |

| ASTM Test | D1003 | D1003 |

| Polycarbonate | 86 | <1 |

| PETG | 86 | 1 |

| ECTFE | - | - |

| PVC | - | - |

| ETFE | - | - |

| Engravable Sheet | - | - |

| Polypropylene | - | - |

| PCTFE | - | - |

| FEP | - | - |

| ABS | - | - |

| HDPE | - | - |

| EVA | - | - |

| High Impact Polystyrene | - | - |

| UHMW | - | - |

| PEEK | - | - |

| PPS | - | - |

| PET | - | - |

| Acetal | - | - |

| Acrylic | 92 | 2 |

| Expanded PVC | - | - |

| TPE | - | - |

| PTFE | - | - |

| LDPE | - | - |

| Paper Boards | - | - |

| Fluted Polypropylene Boards | - | - |

| Foam Boards | - | - |

| Polycarbonate Film | 89 | <1 |

| Polyester Film | 93 | 1.5 |

All statements, technical information, and recommendations contained in this table are for informational purposes only. Kingstar building material does not guarantee the accuracy or completeness of any information contained herein and it is the customer’s responsibility to conduct its own review and make its own determination regarding the suitability of specific products for any given application.