- Products

- Applications

- Resource Center

TECHNICAL GUIDES & DATA SHEETS

MATERIAL SELECTION TOOLS

ARTICLE & PRESS RELEASES

- Contact Us

- About Us

The abbreviation PVC stands for polyvinyl chloride. Foamed PVC is also called foam board because it consists of a plastic foam core that is laminated with paper on both sides. With several variations, including Expanded PVC, also known as PVC Foam. Sometimes Foam PVC is referred to as Foam core board.

Polyvinyl Chloride is a versatile thermoplastic polymer that is lightweight, durable, low cost and easy to process. PVC Foam has a wide range of applications including; POP/POS displays, exhibits & kiosks, framing, interior and exterior displays, packaging and more.

PVC is a popular sheet material that is used in a wide range of industries, from sign making to mechanical engineering. The diversity of applications has everything to do with its properties of workability and insulation. PVC can be formed into any shape. That is why it is mainly used for products with complex shapes.

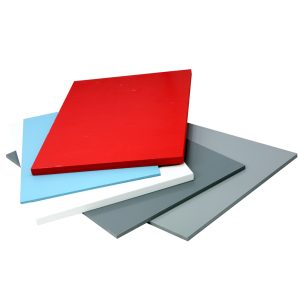

The material is available in two types: foamed PVC and hard PVC. On our website (kingstar.biz), you will find both types, in different colors and in sheet thicknesses of 1 to 30 mm (hard) and 1 to 30 millimeters (white foamed).

PVC sheets are available in two types: solid (hard) and foamed (foam board) sheets. It is important to know the difference between the two types of PVC sheets because they each have their own applications and processing options. Whatever type of PVC sheet you choose, you are always assured of a long life of the sheet and good recyclability.

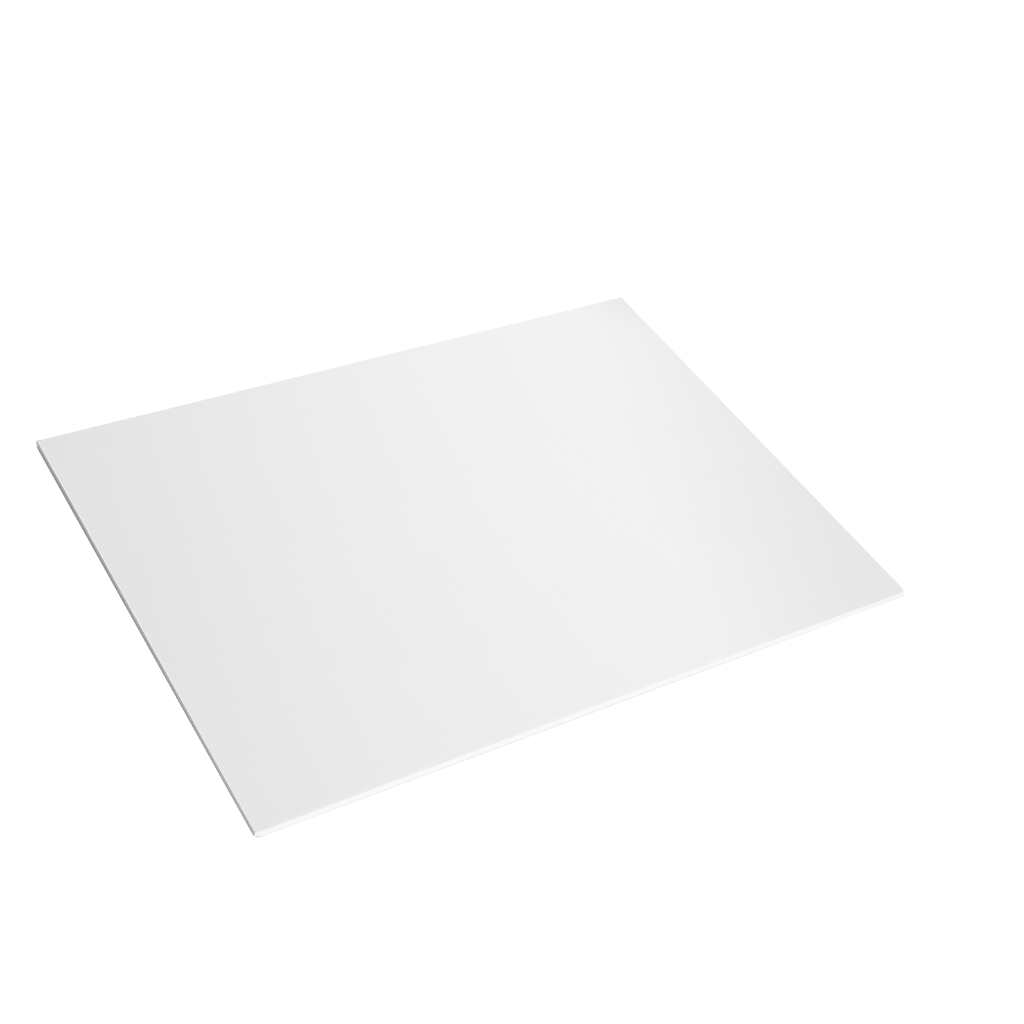

Foamed PVC

Foam PVC is an extruded light weight, rigid PVC thermoplastic sheet. Combining a closed / tight cell structure together with a uniform smooth (slightly ‘orange peel’) surface finish. Producing a lightweight, extremely robust sheet that is tough, impact, chemical and water resistant. Foam PVC sheet offers a superior substrate for direct colour printing.

Foamed PVC sheet is a particularly light material. These sheets weigh less than half a gram per square centimetre. That is half the weight of a standard PVC sheet! This type of sheet is very suitable for the advertising industry because it is easy to cut and print.

PVC foam boards can be divided into free foaming, Celuka foaming (skinned foaming), co-extruded foaming, and wood plastic co-extruded foaming boards according to manufacturing processes.

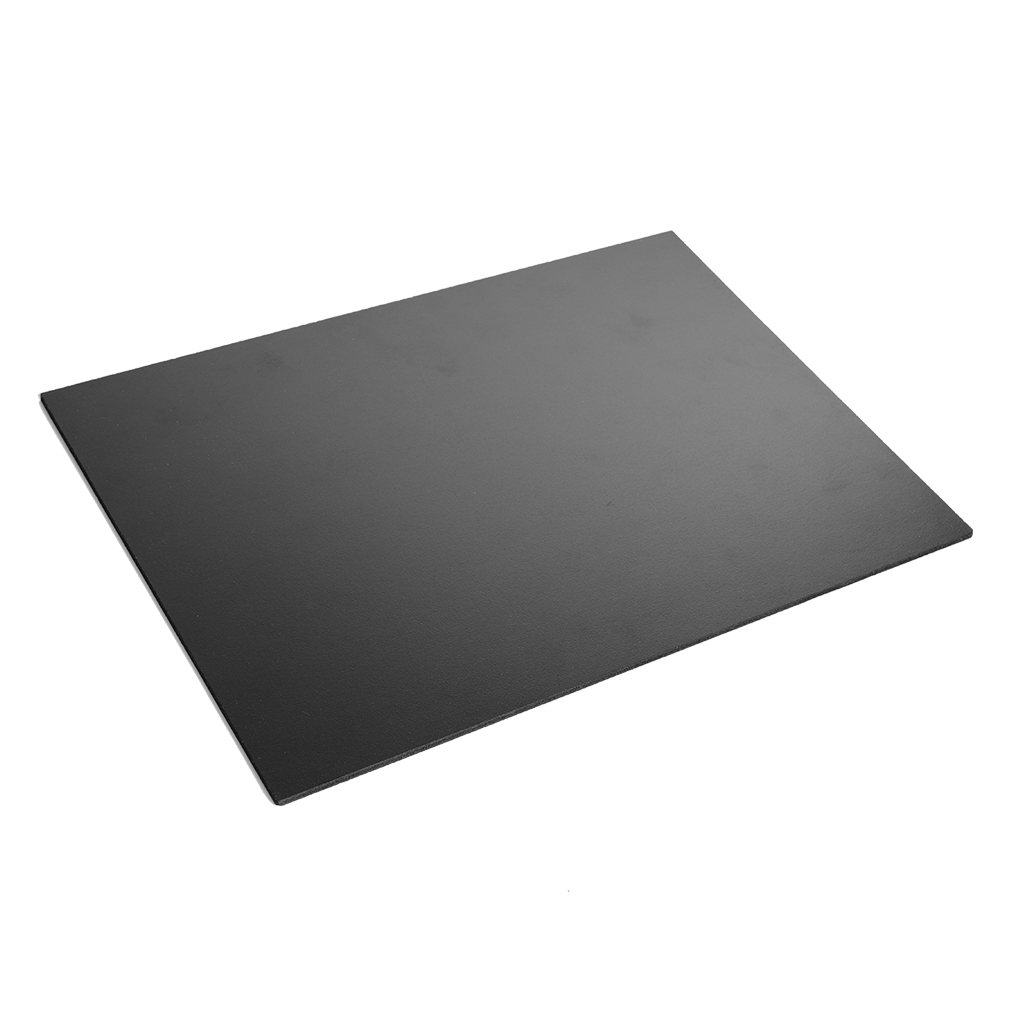

Hard PVC

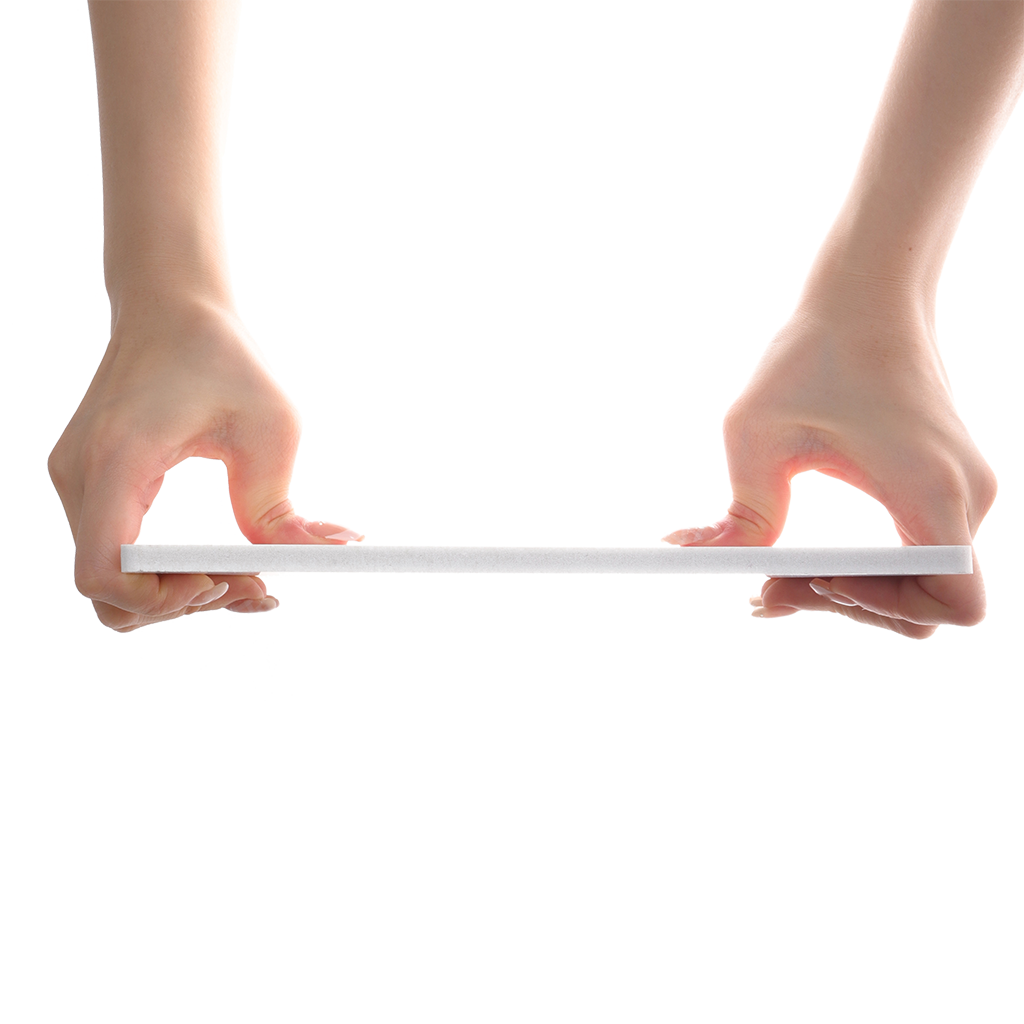

Hard PVC sheets are more rigid, more solid, dimensionally stable and much heavier. In addition, these sheets have good chemical resistance and electrical insulating capacity and are self-extinguishing. These properties make this material very suitable for industrial applications.

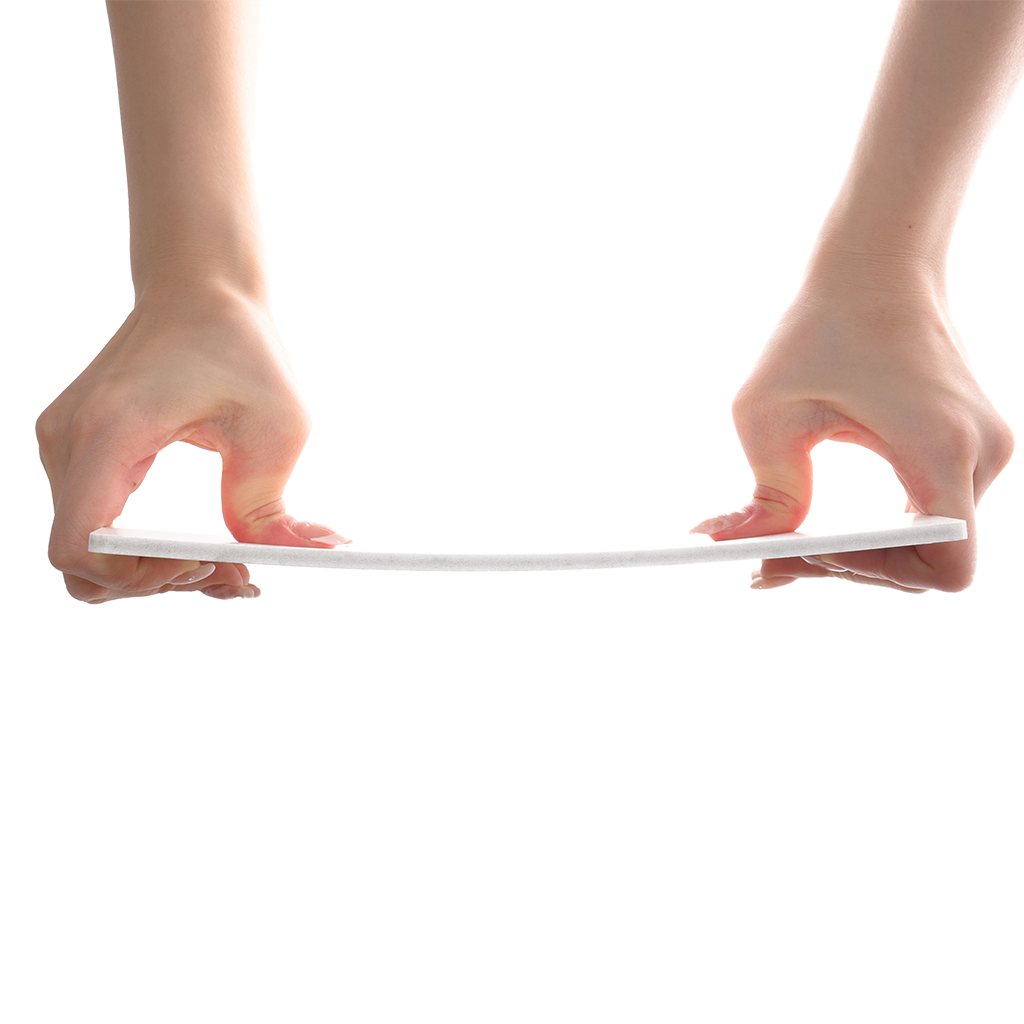

Before deciding on a plastic sheet, it is important to realize the major differences between the two varieties of PVC. First of all, foamed PVC is lightweight plastic; as it weighs less than half a gram per square centimeter. Foamed PVC weighs half as much as solid PVC, making it easy to handle and a choice material for advertising and sign making. Especially, since foamed PVC sheets are also suitable for several printing methods. Many advertising signs in stores are made of foam board. The surface of the material is smooth, but not hard like solid PVC sheets. Foamed PVC’s core consists of PVC foam, which makes the material so light. Foamed PVC sheets have other useful and important characteristics, for example: they are fire retardant and heat and sound insulating. Additionally, the versatile material is suitable for alterations such as drilling, sawing and cutting, making the material a common choice in construction.

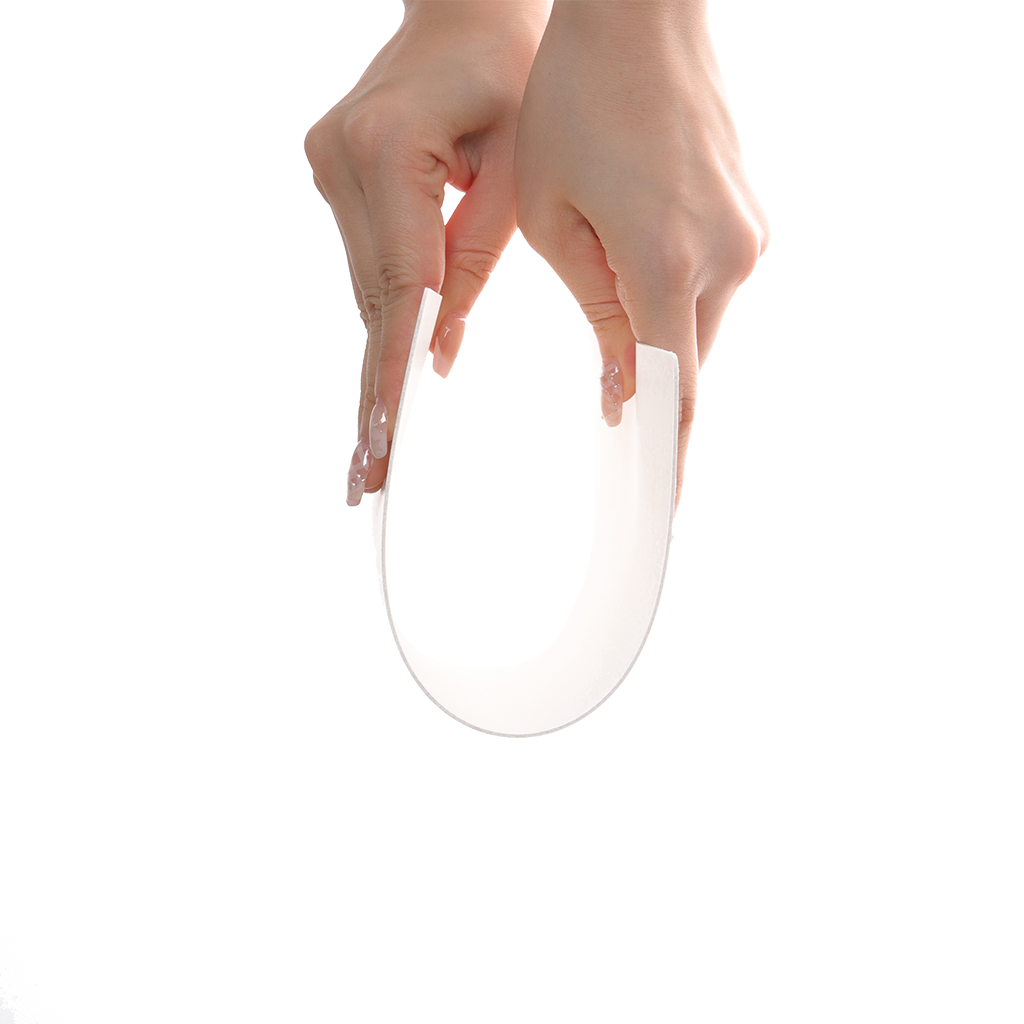

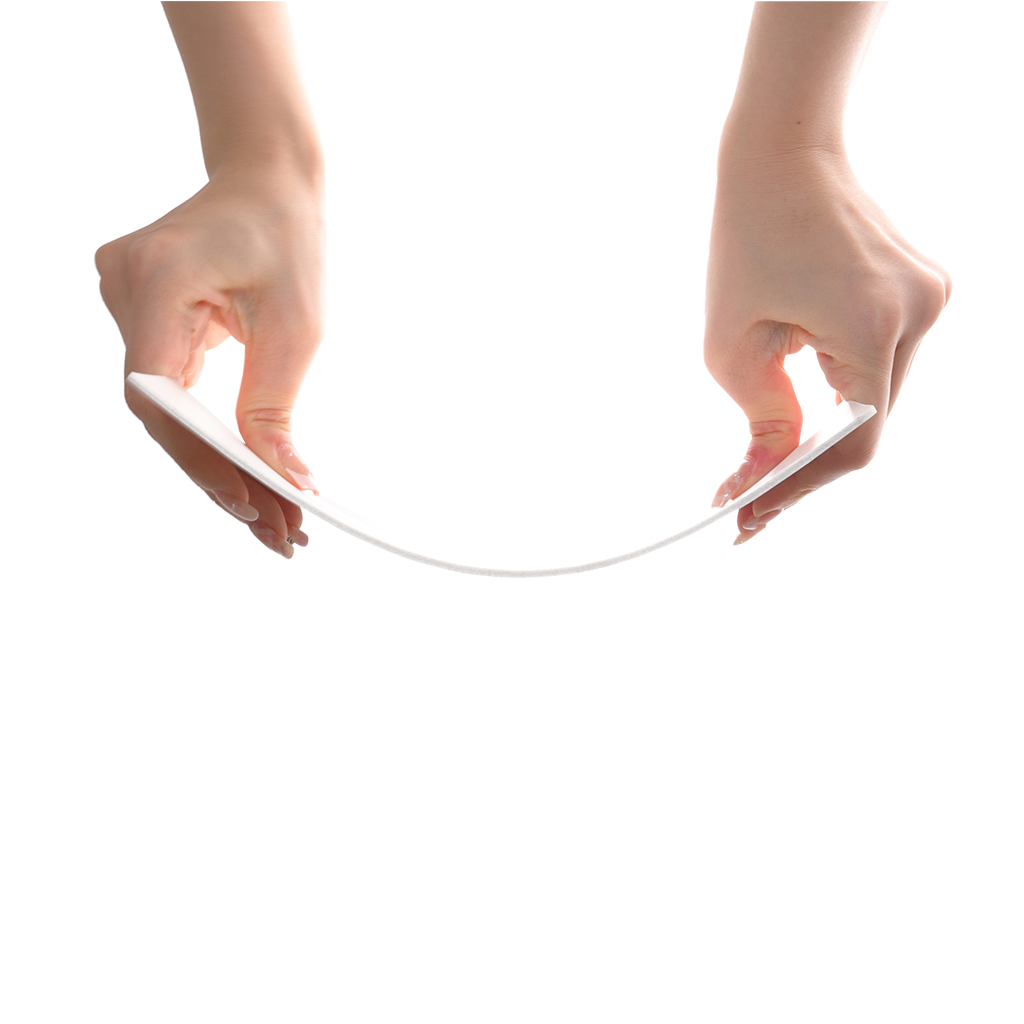

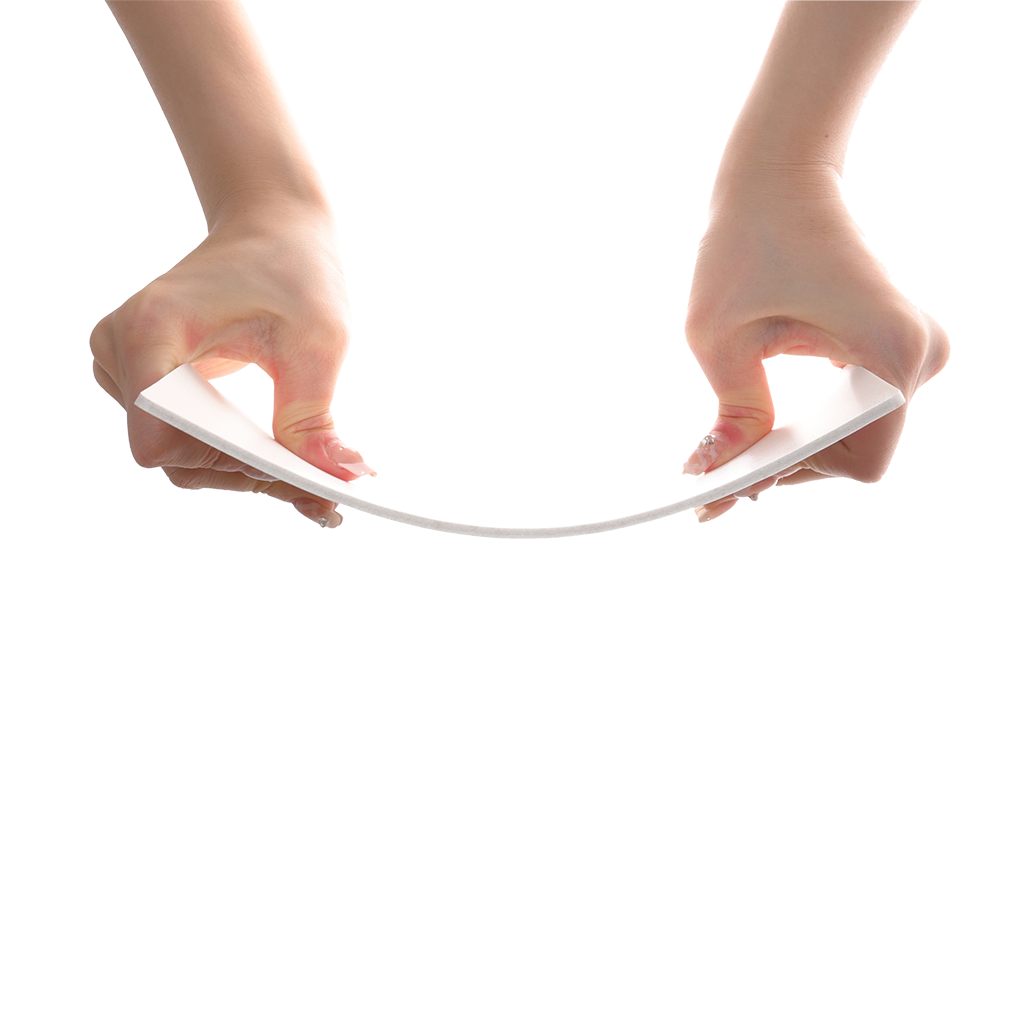

Solid PVC sheets are significantly heavier and stronger than foamed PVC, making them more durable and abrasion resistant. Solid PVC sheets are extremely workable, so sawing and milling are easy tasks. It also helps that the material tends to keep its shape really well, making it suitable for precision work. And after making a notch in thinner sheets (1 or 2 mm thick), the PVC sheets are even foldable. Normally, the material will hardly change shape, even when it’s under pressure. Due to this shape stability, solid PVC sheets lend itself for brace material (adjustment and filling sheets) in heavy duty machinery. Another important quality is solid PVC’s high chemical resistance, which makes the material popular for applications in laboratories and in the chemicals industry. Finally, PVC is well known for being electrically insulating. Solid PVC is therefore commonly used as electric tubing and to cover electric equipment.

■ 50% lighter than solid PVC, very lightweight

■ Matte surface finish, both sides

■ Virtually waterproof – Durable closed-cell structure

■ Excellent moisture resistance does not rot

■ Low thermal conductivity, low heat transmission

■ Vibration and sound absorbent

■ Homogenously colored

■ Chemical, corrosion, and rot resistance

■ Approved for use where food is processed or sold

■ Non-Harmful to humans or the environment in the manufacture, application, & disposal

■ Low flammability

■ Easy to cut and work using common woodworking tools

■ Can be easily bonded, nailed, bolted, or fastened

■ Formable into specific shapes

■ The most economical choice for plastic sheeting!

■ Excellent for direct printing, screen printing, laminating, foiling, vinyl lettering

■ Superior interior and limited exterior applications such as retail displays and signage

The application and desired processability determine which type of PVC suits your project. Do you want to be sure that you are making the right choice? Then please contact our customer service .

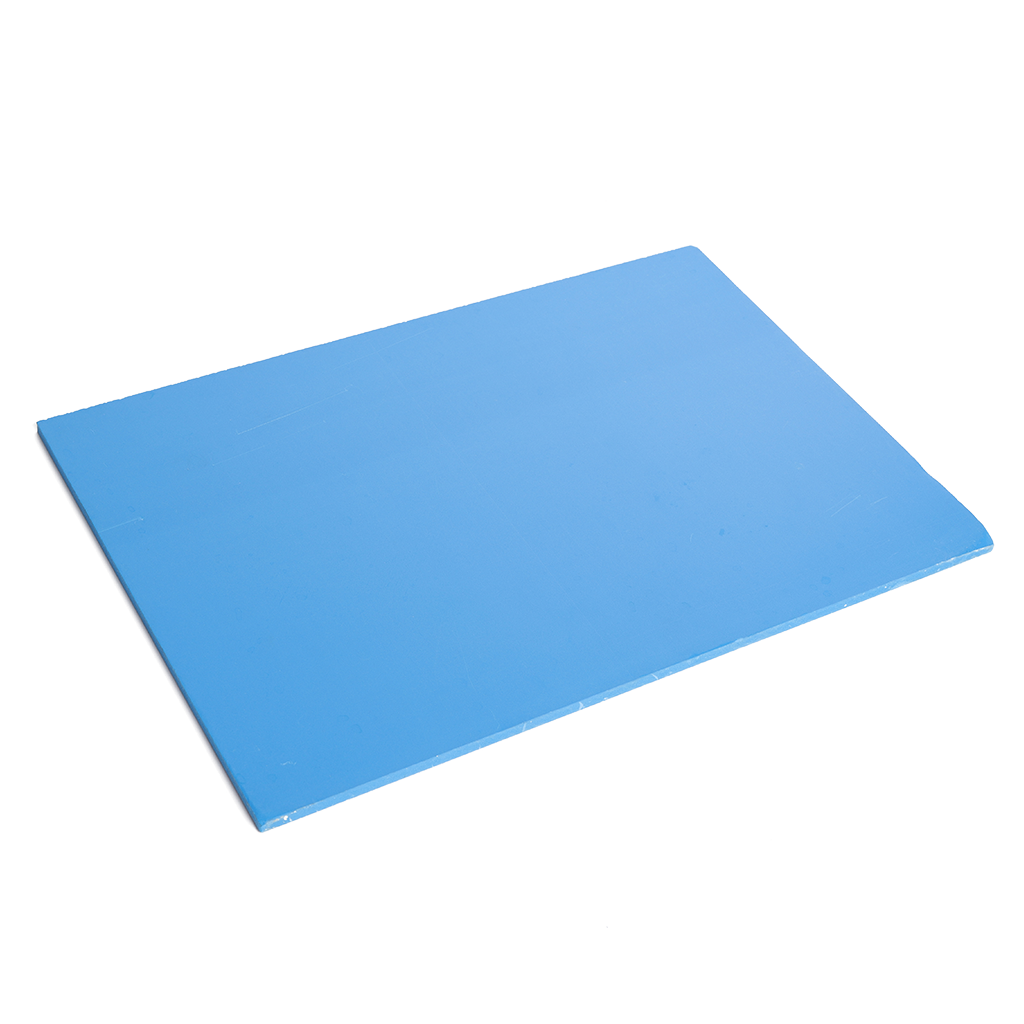

On our website, you will find white foamed PVC, coloured PVC foam board and hard PVC.

In addition to the different colours, you have a choice of different sheet thicknesses, ranging from 1 to 30 millimetres.

1-3mm sheet metal has toughness and is easy to plastic, making it more suitable for making small models.

5-7mm board has high hardness and a curvature of less than 15 degrees, suitable for model walls and sand table floors.

Board with a thickness of 9mm and above are generally not bent, making them suitable for furniture cabinets, fonts, and carving.

We supply PVC foam sheet material in white, yellow, red, blue, grey, green and black. Do you want to know for sure if the colour of the PVC sheet is suitable for your project? Request a sample.

PVC sheets are easy to process. We are happy to explain the various processing options for foamed and hard PVC.

Process foamed PVC (foam sheet)

Foamed PVC can be sawn, cut, drilled, painted and bent. The surface is flat and smooth and can be printed and inscribed very well.

Working with hard PVC

Hard PVC is very easy to machine with machining techniques such as sawing, drilling, milling. Hard PVC can be bent easily using heat (filament).

Let’s get this conversation started. Tell us a bit about yourself, and we’ll get in touch as soon as we can.

Your email address will only be used to respond to your inquiry. The information you submit will be governed by our Privacy Policy

Quote plastic, custom projects. Put us to work for you!

Fill out the form below, and we will be in touch shortly.