Everything You Need To Know Choosing High Density Polyethylene (HDPE) Sheets

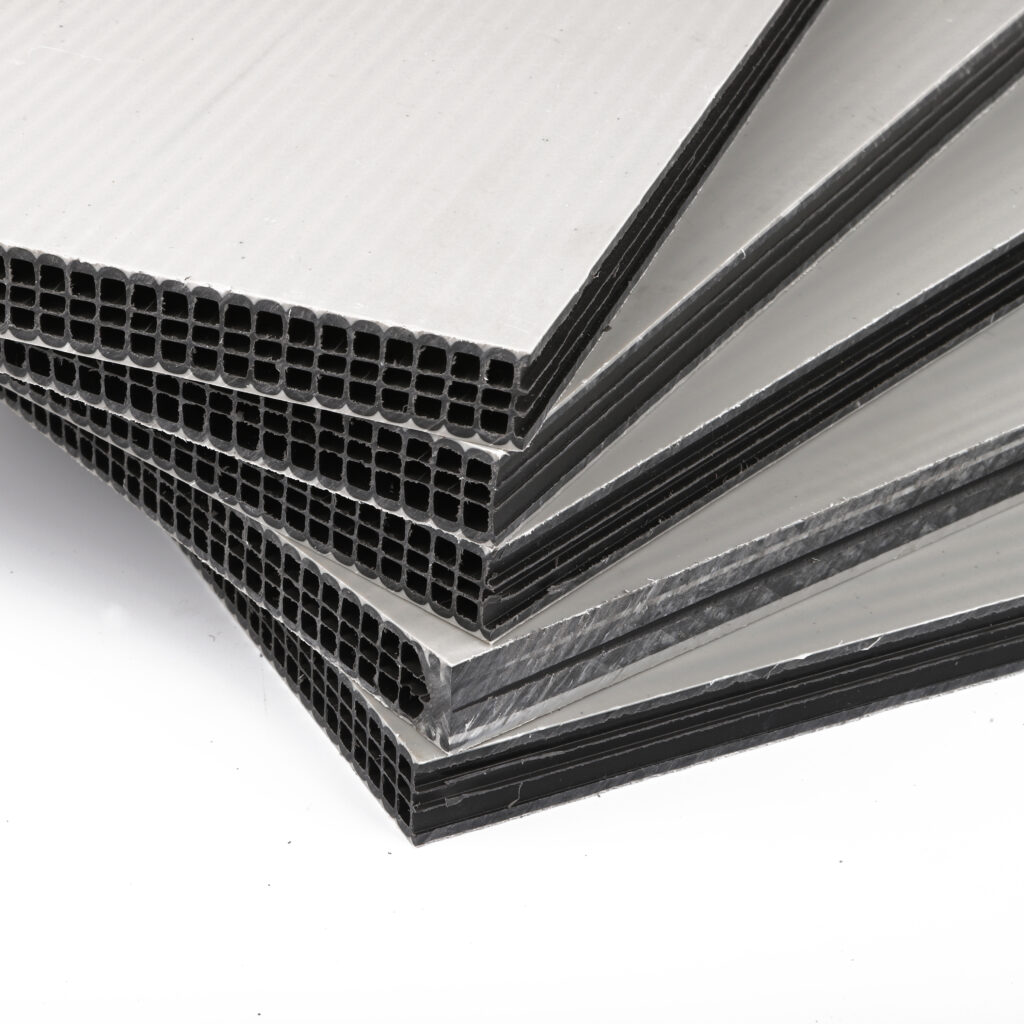

HDPE stands for high density polyethylene sheets. HDPE is a thermoplastic made from petroleum. HDPE comes in a wide variety of forms: black commercial cutting boards are commonly found in restaurant back room prep areas and white plastic cutting boards and cutting sheets are commonly found in front of house prep areas or buffet lines. HDPE can be cut to any size and rounded at the edges to fit any commercial or industrial cutting board application desirable. When rounded, the edges are extremely smooth and splinter-free.

This sheet can be heat formed, shaped, and welded to fabricate ducts, hoods, and much more. The material cannot be cemented, but it is easily welded with a plastic welder. It can be cut with a carbide-tipped saw blade and drilled with regular metal bits.

Another big advantage is that dirt and other substances have difficulty adhering to HDPE. This is ideal for some applications. However, this makes it more difficult to glue or stick the material.

Able to resist deterioration, Kingstar to resist deterioration, Kingstar’s HDPE plastic products are long-lasting, resilient, and strong. HDPE plastic is an incredibly sturdy material, which has only a slightly greater density, yet a higher level of durability than low density polyethylene.

Properties of HDPE Sheets

■ Virtually unbreakable – even at low temperatures.

■ Weldable – suitable for fabrication

■ Light weight – easy to handle without special equipment

■ Excellent temperature resistance

■ Electrical insulation – it is a good insulator

■ Weatherproof – it doesn’t absorb water

■ Low Coefficient of Friction – does not require any lubrication providing low drag load and reduced energy consumption

■ Physiologically inert – approved for food applications

■ Chemical resistance – resists corrosive chemicals

Applications Of HDPE Sheets

■ Plastic Fabrication

■ Tanks

■ Storage Vessels

■ Waste Water

■ Chemical Process Industry

■ Food Industry

■ Cutting Boards

The processing possibilities of HDPE Plastic Sheets

HDPE can be processed in many ways. In general, it is problem-free if you want to drill, turn, mill, hot bend or saw it. What is even more convenient is that HDPE can also be welded very well, allowing several sheets to be permanently fused together. For this, you can use HDPE welding wire. Since many other materials are difficult to bond to HDPE, gluing or sticking is usually not an option.

Drilling

Milling

Sawing

Sawing (circular saw)

Sawing (jigsaw)

Bending (warm)

Turning